Festo Ltd

Address:

Technology House,

1 Fleetwood Park, Barley Way,

Fleet

Hampshire

GU51 2QX

United Kingdom

1 Fleetwood Park, Barley Way,

Fleet

Hampshire

GU51 2QX

United Kingdom

Festo Ltd articles

Displaying 1 - 20 of 51

Secure cloud interface enables manufacturers to start industry 4.0

A new Cloud interface for smart Festo products is being launched by Festo. The CPX-IOT Gateway is a secure, low-cost and easy-to-implement digital solution, enabling users to enter into the world of digitalisation and data analytics in an easy-to-manage and entirely safe way. It provides the first step for companies wanting to develop Industry 4.0 proof of concept or pilot projects with simple, programming free, on-boarding.

16th November 2018

One-day seminar on basics of Industry 4.0

With a strong market demand Festo Training & Consulting has launched a new seminar entitled ‘The Fundamentals of Industry 4.0’. The one-day course – the first of which takes place on 8th March 2018 – is suitable for those who wish to gain a broader understanding of what Industry 4.0 is about: without talking about products.

23rd February 2018

Taking a focus on smarter automation

Festo will be showcasing its new developments and solutions for smarter automation, at this year’s Drive’s & Controls Exhibition in the Smart Industry Expo. Festo will be presenting new developments and products in Industry 4.0 technology; as a user within their own production, as the leading provider of training equipment and courses and as an automation product manufacturer.

24th January 2018

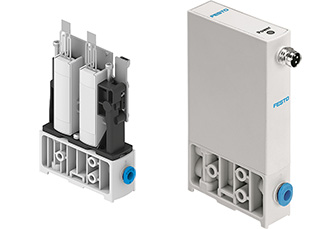

productronica: Piezo technology sparks revolution in automation

productronica provided the launch pad for Festo’s Motion Terminal VTEM which it says will catapult pneumatics into the era of Industry 4.0 ‒ with apps that can replace over 50 individual components. All this is made possible by the latest developments in piezo technology and software.

14th November 2017

Piezo valve technology helps to increase accuracy

A range of piezo valve-based pressure regulators from Festo help to deliver smooth, precise pressure control and metering suitable for a range of applications. Originally, the characteristics of piezo valves made them well suited for medical applications, as Paul Kendall, MedLab sector specialist for Festo UK explained: “Piezo valve technology has low energy consumption, does not generate heat and is silent in operation - so that it won’t disturb patients under treatment. Critically, the technology is also non-magnetic and so will not interfere with any other medical equipment.”

6th November 2017

What are the biggest challenges facing machine builders?

In this article, Warren Harvard, Product Manager for Electric Drives at Festo, discusses the challenges facing machine builders and what can be done to improve the easier selection, connection and configuration of electric drives solutions. For special purpose machine builders, being able to specify a solution quickly and easily with total confidence in the performance is key to winning business in an efficient manner.

2nd October 2017

Knowing your poppets from your spools

Offering free advice to help engineers designing and specifying pneumatic systems, Festo aim to help customers select the best valve for their application. The intention is to give confidence when choosing from the company’s Blue Star Core Range of products, which are available for next day delivery and combine proven Festo quality with attractive pricing.

22nd March 2017

Tip-top tips for optimising air preparation

A series of technical resources designed to help engineers optimise air preparation to improve process reliability, machine availability and service life in pneumatic systems has been developed by Festo. Available online engineers can view a series of short tutorial videos, review the top tips summary or download a white paper entitled: ‘Compressed air preparation in pneumatics.’

21st February 2017

Optimising liquid handling with modular dispense head

Launching a new modular dispense head, Festo introduced the VTOE, which simplifies and speeds up the processing of laboratory samples, while providing a high degree of accuracy. Diagnostics laboratories are faced with the challenge of managing ever greater volumes of specimens without losing accuracy or flexibility of service.

13th January 2017

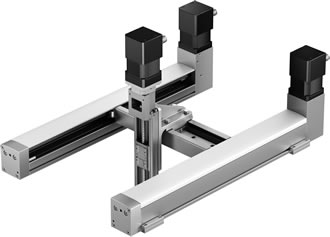

Higher performance delivered in EXCT handler

A new handling system has been launched by Festo, the EXCT handler, which delivers 30% higher performance than traditional gantry systems. It provides advanced dynamic positioning and motion control in pick and place and assembly applications, delivering high accuracy so end-users can increase productivity and reduce operating costs.

15th November 2016

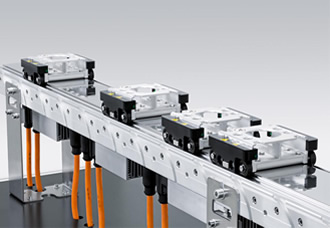

Delivering Industry 4.0-ready intralogistics

An Industry 4.0-ready linear motor track system, has been announced by Festo, the Multi-Carrier-System (MCS), which was jointly developed with Siemens. Winner of two 2016 PPMA Industry Awards, for Most Innovative Automation System and Partnership of the Year, MCS is an adaptable, modular transport solution for manufacturing and production, combining linear motor and mechanical guidance technology from Festo with Siemens’ extensive controls expertise.

30th September 2016

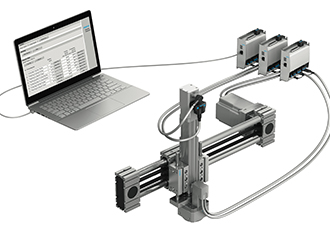

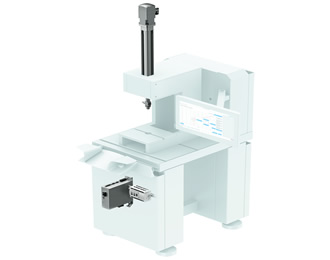

Easy-to-use alternative to traditional press control systems

Now offering high-precision manufacturers of electronics or other small parts a lower cost, easy-to-use alternative to traditional press control systems is Festo. Combining software and hardware components from Festo into a complete mechatronic solution, the servo press kit YJKP enables electric press-fitting applications requiring up to 17kN force to be implemented simply, reliably and cost-effectively.

2nd September 2016

Driving the benefits of Industry 4.0

To assist plant managers and engineers to realise the benefits of smart manufacturing and Industry 4.0 principles, Festo has embedded OPC Unified Architecture (OPC-UA) into its valve terminals. The valve terminals, which control factory and process automation and combine fluid and motion control, can now be seamlessly embedded in any Industry 4.0 host environment, supporting factories of the future.

1st August 2016

Award-winning EMCA integrated positioning drive

Festo has introduced its EMCA positioning drive, consisting of a maintenance-free and wear-resistant brushless DC motor with integrated power and control electronics. The integrated drive system is compact, avoids long motor cables, improves electromagnetic compatibility and reduces installation workload and space requirements, while built-in monitoring functions ensure safety and reliability.

9th June 2016

Flow & pressure sensors feature IO-Link

Festo has launched two new easy-to-use sensors with IO-Link output that enable engineers to check the status of their processes readily and increase production efficiencies. Developed in repsonse to the trend for increased monitoring and diagnositcs, SFAW is the first flow sensor from Festo for sensing liquid media and the SPAU is a new modular system designed for the monitoring of pressure and vacuum in process and factory automation applications.

9th February 2016