Compact plug-and-play handling system simplifies commissioning

A compact handling system which combines kinematics, controller and software in a single kit to enable engineers and OEMs to save time and money, has been introduced by Festo.

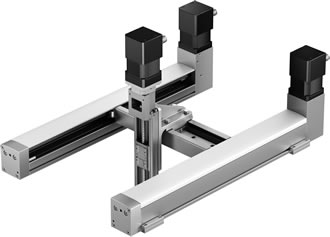

Based on standard Festo components for optimum reliability, the YXMx compact handling system is suitable for a wide variety of positioning, pick-and-place and other assembly applications: such as screwdriving, dispensing, testing, soldering, gripping, and opening and closing containers. The system is delivered ready for use either as a basic stand-alone module, or for integration into serial machines. All the user needs to do is input its own data parameters and the YXMx is ready to go.

Warren Harvard, Product Manager at Festo, explained: "Our new compact handling system has been developed to reduce time to market and save costs by providing a plug and play solution that can be quickly and easily installed, integrated and programmed."

Harvard added: "The YXMx has been developed as a cost-competitive desktop solution that is simple to use and keeps engineering work down to a minimum – saving time and money."

The standard kinematic functions for the YXMx are delivered via a planar surface gantry based on Festo’s EXCM to provide excellent installation space to working space ratio and scalability. The system features twin stepper motors with integrated controller and converter and a parallel kinematic drive to move the end effector rapidly and accurately to any X-Y co-ordinate position as standard. Additional options include a Z-axis and remote camera for vision.

The YXMx compact handling system is equipped with a CECC-X compact controller that enables it to communicate with the production line and with other YXMx systems when used in sequence. A range of predefined interfaces to a master control system are included, along with the OPC-UA interface to make the system Industry 4.0 compatible.

To speed up programming and commissioning, the installed software library incorporates various predefined function block elements for CODESYS, such as: point to point, 3D path interpolation, homing and jogging of the kinematic system, sequence processing, file management and error handling.

Similar articles

More from Festo Ltd

- Secure cloud interface enables manufacturers to start industry 4.0 16th November 2018

- How to maintain network security in Industry 4.0 13th July 2018

- One-day seminar on basics of Industry 4.0 23rd February 2018

- Taking a focus on smarter automation 24th January 2018

Write a comment

No comments