Easy-to-use alternative to traditional press control systems

Now offering high-precision manufacturers of electronics or other small parts a lower cost, easy-to-use alternative to traditional press control systems is Festo. Combining software and hardware components from Festo into a complete mechatronic solution, the servo press kit YJKP enables electric press-fitting applications requiring up to 17kN force to be implemented simply, reliably and cost-effectively.

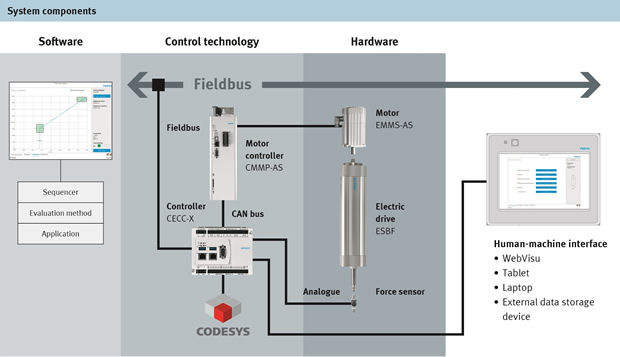

Whether the application is press-fitting printed circuit boards into housings, inserting and verifying pins in a plug or bending and forming components, Festo’s servo press kit YJKP delivers a simple system solution. It comprises modular operating software and standard Festo hardware components, the electric spindle drive ESBF, the motor EMMS-AS, the motor controller CMMP-AS, the controller CECC-X and a closed loop feedback force sensor.

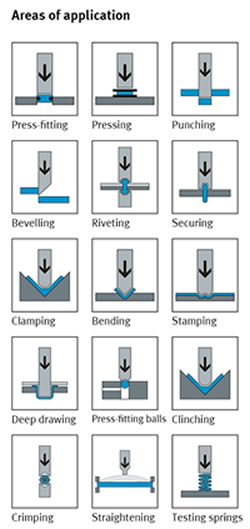

The configurable servo press kit can be tailored to the needs of each user or application, ensuring flexible design and reducing investment costs. This is advantageous since most engineers acknowledge that in 90% of cases, they use only 10% of the capabilities of a traditional pre-assembled press from an established manufacturer. Festo’s modular system allows users to select a force range of 0.8-17kN, stroke lengths of 100-400mm, axial or parallel attachment of the motor, and a single-turn or multi-turn encoder. In other words, they choose only the functionality needed, thus avoiding costly over-specification.

Easy-to-use operating software is pre-installed in the controller, ready for use as soon as system integration is complete. No programming skills are needed and parameterising the press unit is simple and intuitive. Modular software offers a range of application-specific functions which can be displayed on any platform, on a PC, tablet or other HMI.

With function elements in the software’s integrated library, processes are quick to configure, reliable and easy to implement. Monitoring is simple, as all steps can be fully checked and tracked for quality assurance using the software, and users can reload the results of each individual stage if needed. Evaluation and control procedures for the envelope curve, threshold value and windowing are already integrated into the software. The innovative servo press kit also has a number of smart pre-configured functions and an OPC-UA interface that is compatible with Industry 4.0 environments.

“The servo press kit is another example of the kind of complete mechatronic solution that our customers are increasingly demanding,” said Steve Sands, product manager, Festo. “It delivers easier commissioning, set-up, and configuration, as well as improved reliability and usability, all at a lower price-performance ratio than traditional alternatives, optimised for their application. All of which makes it an attractive proposition for machine builders and customers who want to integrate into existing infrastructure and focus on the tooling and task in hand.”

Sands added: “Using standard hardware components and pre-built software from a proven single supplier also guarantees faster delivery and easier access to spares.”

Similar articles

More from Festo Ltd

- Secure cloud interface enables manufacturers to start industry 4.0 16th November 2018

- How to maintain network security in Industry 4.0 13th July 2018

- One-day seminar on basics of Industry 4.0 23rd February 2018

- Taking a focus on smarter automation 24th January 2018

Write a comment

No comments