Piezo Ceramic Discs are the "Heart" of the Sensors

Automated industrial production of industrial goods in the highest quality would not be conceivable without ultrasonic sensors. They are indispensable in automation and among other things, are used for measuring distance and filling levels, for attendance monitoring or level adjustment. They check the gap between objects and therefore supply state variables for control. Therefore, the transducers are always the most important components in an ultrasonic sensor. As transmitters, they convert electrical signals into ultrasound and as receivers; they convert the very low pressure fluctuations of ultrasound in the air to electrical signals. Piezo ceramic disks, which act as the "heart" of the transducer, therefore play a key role.

Ultrasound is above the audible frequency range for humans and offers numerous possibilities: A simple example of this is to detect a presence from an echo or determine the distance of an object from the runtime. But, sound signals can also supply even more information. They are able to give information on the properties and the motion state of the reflected object or the transportation medium and recognize patterns of information. With corresponding effort, ultrasound can also be used for orientation – in the same way as bats and dolphins.

Sensor engineering with a wide spectrum of use

SECO Sensor Consult GmbH with headquarters in Coburg, Germany, has been considered the specialist for ultrasonic transducers for many years. The company has been developing and manufacturing piezo-based ultrasonic transducers for air and gas applications, which are used in various different fields since 1996 (Image 1). Depending on the version, the transducers operate at frequencies of 60 to 600 kHz, achieve ranges from 10 m down to 1 cm and at high resolutions in the millimeter range with repeatability rates of less than 10 ms. Possible applications include automation technology, printing machines, packaging technology and many other fields:

Miniaturized pulse converters for example, support analysis technology in biochemistry and laboratory medicine. In the meantime, the importance of robust ultrasonic sensors for use in mobile work-horse machines such as those used for agricultural technology or road construction is increasing. For example, ultrasound controls are used in tar machines to control the gap of the surface of the tar to a reference cord. In medical technology for example, high-performance ultrasonic transducers are relied on for measuring the function of the lungs or for respirators.

The Basic Structure of the Piezoelectric Transducer

Piezoelectric ultrasonic transducers make use of a piezoceramic disc as an electromechanical transducer. The generation and detection of ultrasound is the classical piezo application. An electric voltage is generated under force (direct piezo effect) and the dimensions change under the influence of an electric field (inverse piezo effect). Piezo elements convert mechanical energy into electrical energy and vice versa.

The piezo effect is based exclusively on displacements within the crystal lattice of the piezoelectric element. Therefore, there is no mechanical friction or wear in the classical sense and sensitivity is high. Even the smallest deformation results in immediately measurable load displacement. Inversely, a small electrical voltage results in immediate displacement. Piezo elements can therefore be used as sensors and actuators at the same time as they not only generate ultrasound but also detect it. Of course, the short response times and the high dynamics of their displacement also benefit ultrasound generation.

Quality is Imperative

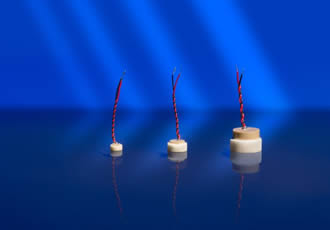

In ultrasonic transducers, the piezoceramic disks are glued to a specially adapted layer that transmits the sound energy effectively to the medium of air or gas (Image 2). "To achieve the best possible results, we only use our proprietary adaptive material", explains Thomas Möckl, managing partner at SECO. “It consists of a particularly light epoxide filled with hollow glass spheres that is exactly defined according to its acoustic properties." An electrical line soldered to the piezo ceramic then completes this functional elementary oscillator.

Normally, it is then fixed into cases using PU casting resin. This serves as protection for the mechanical system, reactionless holding and electrical shielding.

The piezo ceramic used in the transducer must also meet high requirements. As key components, they also considerably influence the quality of the transducer and therefore the sensors. Möckl explains further, "therefore, we purchase a ceramic specially adapted for our requirements from our main supplier, PI Ceramic. "It meets our standards on quality and can be easily adapted to the respective application requirements because, in addition to the material selected for each application, it is possible to realize different geometric versions and resonant frequencies."

The piezos "Made in Germany" (Image 3) are also distinguished by their very low tolerance of the relevant piezoelectric parameters (resonant frequency, electrical capacitance and coupling coefficients) for ultrasound performance. They also have very high surface cleanliness. This allows optimum, solid and at the same time, elastic bonding to the adapted layer. "The geographical proximity to our supplier is a further argument that is not to be underestimated", continues Möckl. "For example, PI Ceramic always responds very quickly and flexibly to special requests." Therefore, the Piezo elements "Made in Germany" have not only distinguished the sensor manufacturer in a technical but also a practical respect.

Similar articles

More from Physik Instrumente (PI) GmbH & Co. KG

- Individual service for high-end positioning systems 6th February 2018

- Catalogue for alignment of optics and SiP 30th January 2018

- Compact linear stage driven by three-phase linear motor 5th January 2018

- Don't let the shakes ruin your selfie 13th November 2017

Write a comment

No comments