Machining

Displaying 341 - 350 of 460

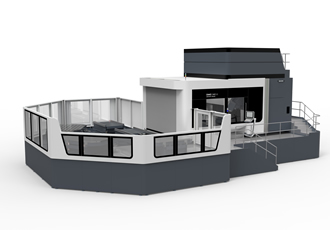

Dynamatic-Oldland Aerospace have DMG MORI Giga Milling Centre

Dynamatic-Oldland Aerospace is installing a DMG MORI DMC 340 U RS4 Giga Milling Centre in a new purpose built unit at its Swindon facility, the first machine of this type in the private sector in the UK. With a capacity of 3,400 mm in X, 3,400 mm in Y and 2,000 mm in Z this machine has four pallets, is capable of handling workpieces of 16 tons, has a rapid traverse rate of 60m/min and a tool magazine holding 180 tools each of which can weigh up to 30 kg. James Tucker, Managing Director of Dynamatic Limited UK says, “The versatility of this machine in the manufacture of complex parts in aluminium alloy, steel and titanium alloy fits well into our existing machine pool. The machine, expected to be delivered this June, will help us to serve our existing and new customers and deliver larger and much more challenging parts.”

8th June 2016

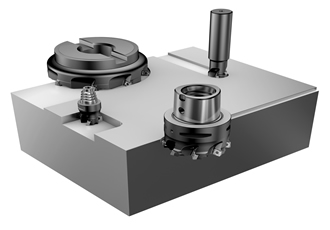

Steel milling grade offers greater security and productivity

Machine shops faced with identifying ways of achieving secure machining with long and predictable insert life in steel milling operations can turn to GC1130, an insert made with the Zertivo, a unique production technology from Sandvik Coromant. GC1130 helps to overcome challenging machining conditions with a clean and intact edge, delivering high metal removal rates and performance levels in both wet and dry machining operations. The grade is offered as the first choice for shoulder milling cutters, CoroMill 390 and CoroMill 490 and chamfer cutter, CoroMill 495.

8th June 2016

High-Dynamic Linear Piezo Nanopositioning Stages

Aerotech’s QNPHD linear piezo nanopositioning stages provide the benefits of both a stage and actuator in one compact, high-stiffness package. With a direct-metrology, capacitive sensor feedback option, high resonant frequencies, and high load capacity, the QNPHD is ideal for a wide range of high-speed and high-precision applications such as scanning probe microscopy, disc-drive testing, and semiconductor wafer articulation.

25th May 2016

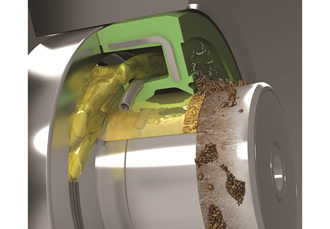

Indiana Evolution

A job shop in the Midwestern US State of Indiana cuts insert costs in half and triples tool life with Beyond Evolution grooving and cut-off tools from Kennametal The Chip Breaking Effect: Direct delivery of cutting fluid to the work zone together with a variety of application-specific chipbreakers provides the Beyond Evolution grooving and cut-off system robust chip control while substantially extending tool life.

18th May 2016

Like a knife through butter

Starrett, has launched a new range of carbide tipped deep cut (CTD) hole saws. The new range is an ideal solution for the repeated intensive drilling of stainless steel, non ferrous metal, aluminium and copper of any thickness up to 25mm. The hole saw is designed for use by contractors in the electrical, mechanical, building, construction, HVAC, plumbing and other fitting sectors.

28th April 2016

New CoroTurn 300 with iLock interface introduced

For longitudinal and face turning, Sandvik Coromant introduces the new CoroTurn 300 for higher component quality, increased handling efficiency and longer tool life in steel turning operations. Available immediately, the CoroTurn 300 features stable insert clamping, as well as eight-edged inserts for the high chip control, tool life and surface finish.

8th March 2016

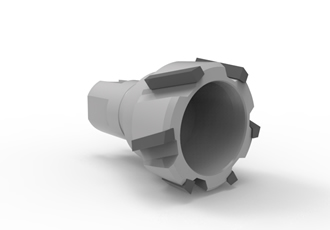

Allied Machine Offers ALVAN Line of Expandable Precision Reamers

Allied Machine & Engineering Corp offers a complete range of ALVAN expandable precision reamers, the ideal tool for high volume production wherever high quality, tight tolerances, or superior finish is critical. The ALVAN line is available through an exclusive supply agreement with S.C.A.M.I., an Italy-based maker of high quality precision reamers. Allied has a large team of in-house application engineers to help select the right product for specific applications, and can customize their reamers through a variety of geometries, substrates, and coatings.

8th March 2016

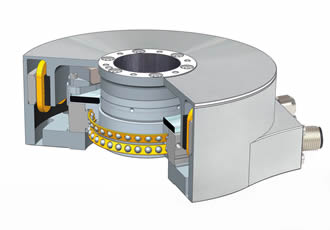

Rotary positioning and measuring to sub-micron accuracy

Companies building CNC machines incorporating rotary axes would normally need to source and assemble a torque motor, a precision bearing and a high resolution angle encoder. All three items may now be purchased from Heidenhain as a single, compact unit following the company’s introduction of two new modules, designated SRP 5080 and SRP 5010, fitted with an incremental and an absolute encoder respectively.

7th March 2016

Machining documents

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex