Sensors technology integration enhances strain gauges

Proprietary Advanced Sensors Technology has been successfully integrated into strain gauge products by the Micro-Measurements brand of Vishay Precision Group. Advanced Sensors Technology applies tangible specification and manufacturing process improvements, along with industry-exclusive strain gage sensor design techniques, for direct customer benefit.

Strain gauge technology, as a key internal component of finished sensor designs, is a long-recognised industry standard.

The strain gauges are used to detect a change in electrical resistance, occurring in response to an applied force. In addition to their reliability, strain gauges are relatively compact and low cost.

This has facilitated their widespread adoption into many of today’s force, load, position, pressure, tension, weight, and strain sensor designs.

Such traditional designs have typically called for the bonding and soldering of anywhere from one to four individual strain gauges within a single proprietary configuration.

Among these, the full Wheatstone bridge, a four-strain-gauge arrangement, has consistently offered the highest measurement accuracy, sensitivity and extraneous temperature cancellation.

Further design improvements over traditional strain gage types include smaller and tighter grid-resistance tolerances, improved gauge-to-gauge repeatability, and enhanced measurement stability.

All enhancements are implemented via a fully optimised fabrication process, incorporating the very latest in tooling, methods, and equipment.

As a result, the prototype design and manufacturing of anywhere from a single strain gage piece up to OEM volumes may be easily accommodated, with uniform high quality and competitive lead times.

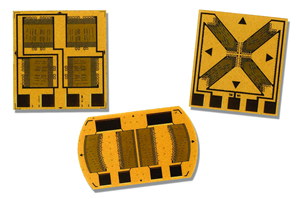

The Micro-Measurements Advanced Sensors Technology product portfolio includes linear, shear and circular gauges, arranged as individual, half-bridge and full-bridge configurations, in ranges from 350 Ω to 20 kΩ, with added flexibility in mounting options.

The technology improves grid-to-grid tolerances and matching over traditional strain gauge manufacturing techniques, enabling better sensor performance.

In the case of full-bridge gage configurations, all intra-bridge connections are integrated directly into the pattern itself, eliminating the need for traditional intra-bridge soldering. The addition of gold-plated solder pads improves solder-joint reliability, while reducing the risks of solder pad oxidation prior to lead wire attachment.

These processes further ensure the close matching of grid-to-grid thermal characteristics and bridge circuit thermal output cancellation specifications, both of which are essential to strain gauge measurement accuracy.

Similar articles

More from Vishay Precision Group (VPG)

- Data acquisition software allows simultaneous sampling of 48 channels 29th November 2017

- PROFINET support boosts measurement amplifier capabilities 2nd November 2017

- Weight indicator boasts 10X expanded memory 7th July 2017

- Extensometer meets EN15000 and EN280 safety applications 25th June 2017

Write a comment

No comments