Predictive maintenance and optimal use of resources

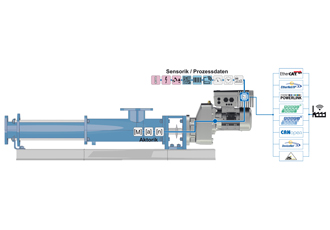

Cost-efficient and reliable virtual sensor functions for condition monitoring have been developed by NORD DRIVESYSTEMS. In applications with steady long-term load profiles, the drive PLC determines the best oil change interval without costly sensors.

The meaning of virtual sensors is explained using the oil lifespan as an example. This is to empower drive technology to schedule maintenance dates solely based on calculations, with no expense for hardware sensors.

The on-board PLC evaluates extensive operational datasets on current, voltage, and speed. From this data available in the inverter, the drive is always able to indirectly infer the current oil temperature. Taking product-specific characteristics of the lubricant into account, oil aging can be determined, allowing for optimal utilisation of the lubricant.

NORD has validated through testing that the calculated oil temperature curve is nearly congruent with the real, measured temperature curve. Working up to launch a fully operational solution soon, NORD is currently validating temperature curves under various load conditions. Predictive maintenance functions are expected to be commercially available in all NORD drive electronics units with an on-board PLC from late 2018.

Similar articles

More from Nord Drivesystems/Nord Gear

- Extruder-type drives for plastics industry 28th January 2020

- Condition monitoring for predictive maintenance concepts 6th January 2020

- Cost reduction through efficient energy-saving motors 11th December 2019

- New products from NORD at SPS 18th November 2019

Write a comment

No comments