When should the coupling insert be replaced?

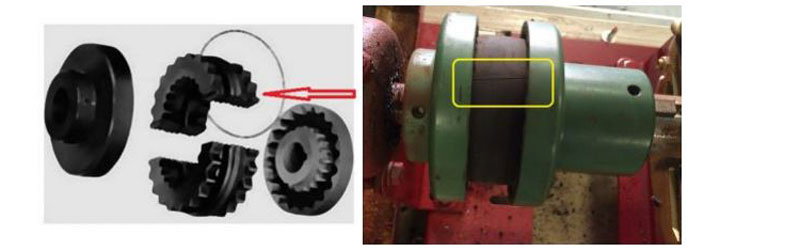

Within industry couplings utilise an elastomeric insert or element. There can be some advantages among this type of coupling.

They include:

- Ease of replacement

- Ability to absorb torsional loading

- No need for lubrication

- Tolerant of slight amounts of misalignment

- Inexpensive

It is important to remember that even though these elastomer couplings can be tolerant of misalignment, the bearings and seals are not, and as such, precision alignment (normally closer than the coupling manufacturer recommends) is necessary. Even with excellent alignment, the coupling element will eventually need replacement.

So, when should the elastomer be replaced? While each manufacturer has good recommendations (read that little piece of paper they put in the box), here are some good indications that is time to replace the element.

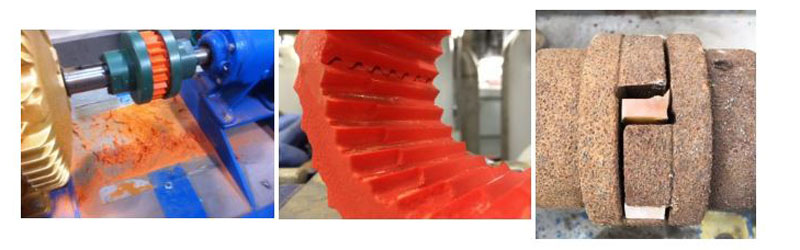

Obvious signs of wear

Remember the most common reason for wear is misalignment. If wear is excessive, then the ability of the insert to transmit power is reduced.

Torsional Damage

On two piece coupling inserts (or one piece inserts in which the two halves are vulcanised together), you may notice a twist in the seam between the two halves. When this twist becomes excessive, the width of the coupling is decreased, which could result in a loss of tooth contact on the hubs.

Elastomer Failure

When some elastomer couplings have run beyond their capacity to transmit power, you may see some of the ‘legs’ of the insert gone, or see the metal jaws making direct contact. In these cases, the entire coupling should be replaced.

In most of these photos, coupling damage is obvious, so one may be led to believe these are extreme examples. But all damaged couplings in these photos were taken by VibrAlign trainers, while teaching training classes in the field. So, these types of failure do occur on a regular basis.

To minimise such failures:

- Make sure the proper insert is being used.

- Perform precision alignment-every time.

- Ensure proper installation and spacing.

- Inspect couplings on a regular basis.

- Replace them as needed.

Save Time. Save Money. Save the Machine.

Similar articles

More from Fixturlaser AB

- Vibration analysis: Where to start? 8th January 2020

- Is this soft foot or are you pulling my leg? 15th February 2018

- It's not the machine, it's you! 4th July 2017

- Roughing in before precision shaft alignment 2nd June 2017

-(1)ed.jpg)

Write a comment

No comments