Rodless cylinder from Parker improves air efficiency and cuts energy costs

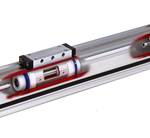

Parker Hannifin has launched a new design of mechanically coupled rodless cylinder that offers production engineers the potential to improve the performance and flexibility of pneumatic systems. In particular, the new P1T rodless cylinder is believed to be the first of its type to eliminate almost entirely the problems of air leakage, while also providing exceptionally low levels of sticktion and break-away force, giving excellent low and high speed characteristics for use in a wide range of applications.

Traditionally, rodless cylinders have suffered from air leakage where the carriage or slide passes through the body of the cylinder; depending on the size and type of cylinder this loss can account for a significant proportion of air used, increasing energy consumption and operating noise. Now, however, Parker has reduced air losses to a minimum by means of an innovative twin-seal design. This is achieved by using a longitudinal polyurethane body seal that lifts and passes through the body of the carriage as it moves, combined with a specially developed polyurethane piston seal that prevents air leakage from the inner face of the cylinder bore, at the point where the piston and carriage connect.

In addition to eliminating the problems of air leakage, this unique design helps to reduce levels of sticktion, or stick-slip movement, and thus to minimise break-away forces. In turn, this leads to far smoother operation, especially at start-up and at low operating speeds down to 2mm/sec, and to improved positional accuracy.

The new P1T rodless cylinder also incorporates a range of other features, including precise, fine-thread needle adjustable cushioning that can be set at any point between fully open and fully closed; porting from either end or single porting from one end in standard end-caps; plus a choice of high load single or dual slide bearings.

The P1T range of rodless cylinders is available in bore sizes from 18mm to 63mm and in stroke lengths of up to 6000mm; all configurations can be supplied in standard or compact versions and include slots within the profile of the body for reed switches. Accessories include magnetic sensors with integrated LED indicators, mounting brackets and shock absorber mounting kits. Depending on specification, the new P1T cylinders can be supplied within 24 hours of order.

Similar articles

More from Parker Hannifin

- Flange system gains new certification for marine applications 4th June 2021

- New generation of oil condition monitoring technology 2nd June 2021

- Parker introduces new low GWP refrigeration dryer series 24th November 2020

- Steering into the future for mobile machinery 17th November 2020

-(1)ed.jpg)

Write a comment

No comments