New bearing wears slowly whilst rotating quickly

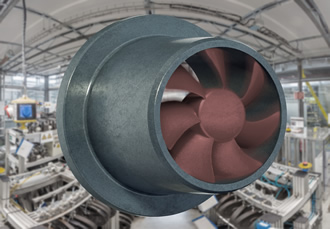

With continuous research and development igus has developed a new material for very high speeds in continuous operation. The iglidur L350 is suitable for use in fans, blowers or electric motors. In rotational tests in the igus test laboratory in Cologne, the material proved its full potential against its metallic counterparts.

Robert Dumayne, Dry-Tech Director, igus said: “iglidur L350 is the perfect alternative to oil-impregnated sintered bearings, both for initial installation and for the retrofit.”

Friction and wear are critical issues, especially where permanently fast rotations prevail. iglidur L350 scores very high compared with other solutions such as metallic sintered bearings due to the much higher resilience against impacts and edge pressure. Test results also showed a three-fold reduction in wear at speeds of 1.5m/s. While sintered bearings reached their limits at still higher speeds, the coefficients of friction and wear for iglidur L350 plain bearings remained constantly low.

Key characteristics of the new material are its low thermal expansion, even at temperatures of up to 210°C. Due to the low moisture absorption properties, the material is also safe in different media. Plain bearings made of iglidur L350 can be calculated and ordered online; the material is also available for the development and production of customer-specific geometries and bearing solutions.

Similar articles

More from igus UK Limited

- From garage business to world leader: igus founders celebrate 90th birthday 22nd June 2021

- VOTW - Metal out plastic in! 10th June 2021

- igus robot works alongside agri-tech startup 18th May 2021

- Tribo-polymers increase machine service life and efficiency 10th May 2021

-(1)ed.jpg)

Write a comment

No comments