Milk plant conveyor saves money with efficient bearings

A UK-based milk processing plant is now achieving an annual saving of £10,000 thanks to NSK, just by switching to an NSK solution following repeated bearing failures on one of its principal conveyors. The milk processing plant was experiencing regular failures of multiple bearings on its conveyor, and as the bearings were located in an inaccessible area this resulted in the inability to provide re-lubrication.

As a result, the customer had to change the bearings every ten weeks, leading to downtime of three hours, which was proving expensive.

Engineers from NSK reviewed the application and after evaluation, proposed stainless steel bearing inserts were fitted with Molded-Oil - NSK´s proprietary oil-impregnated solid material - to help increase service life.

Molded-Oil offers grease-free properties with no requirement for oil refilling as it slowly seeps from this material, proving ample lubrication to the bearing for extended periods of time. This then results in supporting longer service life whilst keeping the environment clean.

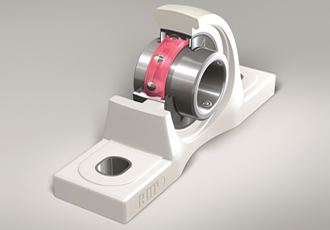

The use of Silver-Lube corrosion-resistant polymer housing was also suggested, which are suitable for applications where frequent wash-downs and optimum hygiene standards are required. The PBT thermoplastic resin housings are paint-free, eliminating any potential for chipping or flaking.

Silver-Lube features nitrile rubber seals, is NSF-approved and available in four different geometries. Suitable for working temperatures from -20 to 90°C, long life and low cost of ownership are among the key benefits.

The combination of Silver-Lube corrosion-resistant housings and the sealing and lubricating properties of Molded-Oil inserts is conveniently offered by NSK´s Life-Lube series, thus delivering increased operating life (with no need for lubrication) in a single unit.

Life-Lube units, which are purpose-designed for applications where contact with process fluids is unavoidable, are available in 20-40mm bore sizes and in pillow block, two- and four-bolt flanges, and take-up unit housings.

Trials of Life-Lube units on the milk processing plant conveyor showed that bearing life was extended from ten weeks to over one year. In addition, there was no longer any need to replace the shaft after each bearing failure. This cost, along with the labour costs associated with deploying two maintenance fitters, as well as cost of lost production time, constitutes the calculated annual savings of over £10,000.

Similar articles

More from NSK UK Ltd

- Pizza plant saves over €15,000 after switching bearings 18th March 2019

- Triple-lip sealed bearing units save €13,000 12th September 2018

- Optimise bearings to avoid production downtime 6th September 2018

- Condition monitoring for bearings improves grinding process 24th August 2018

-(1)ed.jpg)

Write a comment

No comments