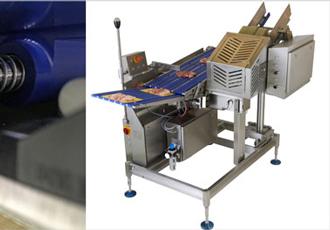

Eliminating production limitations with Thurne slicing equipment

It is amazing sometimes to consider what it takes to speed up a production line – it can simply come down to the performance of a single component. Essentially this is what the team at Thurne came to understand with their bacon slicer technology – and the solution came from close co-operation with Lee Spring as a long-term strategic supplier. Lee Spring was able to create a spring set for Thurne machines that released the potential speed of their CD Mono Card Dispenser, thus rebalancing the whole packaging line.

Alongside speed is the need for reliability since if one component fails in one machine then the whole line stops – again the Lee Spring engineering quality and high specification came to the rescue.

Richard Seager, Technical Director at Thurne explained: “Lee Spring has been a strategic supplier for some time, they are able to work with us on special designs to incorporate and develop custom components which can make a significant difference. This frees us to design innovative machines which go faster than our competitors and help us to grow in the highly competitive international market where we gain the bulk of our sales.”

The Thurne CD Mono Card Dispenser slices and places bacon onto backing cards (L-Boards) used for the display or promotion of customer facing information, marketing material etc., so accuracy is vital, as is speed. Both criteria can be enhanced by reducing the mass of the card transfer carriage which feeds the cards and for this precise control of the return stroke is vital – this is provided by custom springs.

By virtue of their exposed position, these springs (like the machine itself) must withstand regular use of aggressive cleaning fluids in a full wash-down environment which demanded selection of a very special high grade of stainless steel.

Typically the CD Mono L-Board dispenser works at up to 70 packs per minute for 20 hours a day – with 4 hours for shift changes, machine strip and wash-downs – 7 days a week, every week.

Seager explained: “We use springs to shuttle cards quickly sideways and to position them extremely accurately for the pack to sit in precisely the correct position. Then because the carriage has to be free moving to ensure speed of operation the springs are relied on to return the carriage to its correct position after the cards have been ejected ready for the next operation. Speed is all about marrying the forces around the very light weight free moving card transfer carriage. The lighter it is the faster it can operate so Lee Spring compression springs perform a vital function in managing the forces involved enabling us to achieve the required accuracy within a very tight specification, and have demonstrated great longevity and consistent repeatable reliability.”

Mike West at Lee Spring pointed out: “We consider that choice of supplier is often critical to our customers in meeting their performance needs on a long term basis – we therefore seek to develop our technology in the light of these relationships. Thurne came to us with a problem – we came up with a solution and I believe we are both delighted with the result.”

Similar articles

More from Lee Spring

- Drawing attention to the when and why of plastic springs 19th August 2019

- Exotic alloys: what are they and when do you use them? 5th August 2019

- REDUX Wave Springs perform spring function in minimal spaces 24th July 2019

- Metric and imperial springs for pharmaceutical industries 30th May 2019

-(1)ed.jpg)

Write a comment

No comments