Why did the demand for polymers increase during lockdown?

Since Italy became the first European country to enter lockdown on 8th March and the consequent restrictions from governments globally to control the spread of COVID-19, the materials market overall experienced a drop in demand. However, while the demand for many engineering materials dropped, the polymers industry saw continued growth in demand. Here, Ben Smye, Head of Growth at Matmatch, provides insight into Matmatch’s trend data.

As a materials search engine, Matmatch can offer more than material characteristics data and a direct link between design engineers and material suppliers. It also means we can observe trends in demand for various types of materials and how those trends change over time.

It’s from this data that we noticed that, between March and April 2020, the overall demand for metals dropped by 22.6%, ceramics by 36.6%, glass by 13.7% and composites by 0.3%. However, demand for polymers went in the other direction and actually increased during this time.

Materials such as steel, aluminium, other metals and glass are used in a wide range of industries. However, some key sectors for these materials such as construction and manufacturing were limited by lockdown measures. It was, therefore, predictable that the demand for those materials would drop.

Polymers, however, saw an increase as they are suitable for many industries that were providing essential services during lockdown, including the medical, food and packaging industries.

According to data from Matmatch’s database, from the end of January until the time that many Western countries had imposed lockdowns on 29th March, the demand for polymers increased by 20%, while the demand for other materials dropped by almost the same percentage.

It’s only towards the end of April that the materials market saw other materials recover again, which is because industries slowly started getting back to normal. However, the demand of polymers remained much higher than it had been before; by the start of June it was 40% than it was at the end of January.

To have a better understanding about why the demand of polymers increased, Matmatch examined data about the different types of companies using the platform between February and May 2020 compared to the four months before. This revealed that visits from companies in the medical industry increased by 38% in this time. In the same period, medical companies searched Matmatch for polymers that could be used for Personal Protective Equipment (PPE).

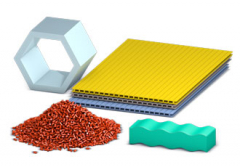

Polymers are lightweight materials, great insulators and resistant to chemicals. These properties make them ideal to produce PPE such as recyclable gloves and face shields. These items have been vital to control the spread of the virus in these months.

More specifically, interest in thermoplastics, a group of polymer materials, increased by 32% between the start of February and the end of May.

Thermoplastics are often used for many medical applications due to their versatility. Some thermoplastics, like ThermoPlastic Elastomers (TPEs), are highly flexible and boast a high elastic modulus that makes them an ideal fit for ventilator bags, masks and tubing. Others, like certain grades of PolyEthylene Terephthalate (PET), are used for implants due to their biocompatibility.

Therefore, the increased interest in thermoplastics is not surprising given the sudden demand from governments and health services worldwide for products that make use of these materials.

During lockdown, demand for two specific types of thermoplastics, polypropylene (PP) and polyethylene (PE), increased by 24 and 19% respectively.

Both materials have a variable crystalline structure that gives them a high level of ductility, tensile strength, impact resistance, resistance to moisture absorption and recyclability. These favourable properties lend themselves to many different applications.

Today, PE is used in hundreds of applications as it is corrosion-resistant, absorbs little moisture and has a low acute and chronic toxicities. Moreover, its solubility and viscosity properties make it safe and ideal for many applications from medical applications like plastic surgery to daily products like plastic bottles or food containers that require high safety standards.

Looking to the future

Since we saw the initial drop in demand across different material categories, things have recovered and overall demand on Matmatch is now higher than it was before the pandemic.

However, there is still the risk of a second wave and some industries might restrict operations again. What happened during the first wave shows that industries like medical, food or those which provide essential services for society, need specific materials.

Trade shows might still be cancelled and travel limitations may continue to be in place until a viable vaccination for COVID is developed. The best solution for design engineers and materials suppliers alike is to ensure they are prepared and can use digital tools to achieve their goals.

Using a database like Matmatch, for example, where there are thousands of materials and materials suppliers from all over the world, can help engineers find the right materials and contact suppliers quickly. For suppliers, it offers a chance to reach new potential customers even when other marketing channels (such as trade shows) have been shuttered.

Similar articles

More from Matmatch

- Using mushrooms to make packaging materials 26th May 2021

- Materials that could bring life to Mars 28th April 2021

- The key environmental indicators in sustainable material selection 19th February 2021

- Guide to sustainable materials now available 25th January 2021

Write a comment

No comments