High tech drive chains make steel looper tower accumulator reliable

To improve the long term operational productivity of its annealing line, Tsubakimoto has helped a steel mill in the Netherlands by replacing lifting chains that failed frequently with ones that have proven to have a working life of 10-15 years or even longer.

As part of the mill’s role of coating sheet steel, a key process is annealing: a heat treatment designed to improve the workability of the metal by heating then cooling the metal to increase ductility and reducing hardness.

This is performed as a continuous process, so the individual sheets of steel must be welded together end-to-end to form an endless strip. Production volumes are such that the welding must be performed automatically.

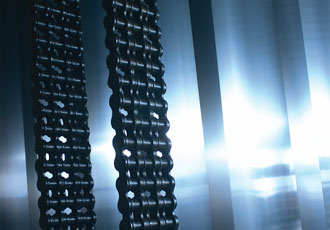

To ensure a steady flow of steel through the annealing line, a looper tower has been installed both ahead and behind of this. These act as accumulators to store a quantity of steel and feed it onto the processing line at a steady rate. At its heart are four hard working chains that raise and lower platforms to accumulate or dispense steel as required.

For the annealing process to be effective, the surface of the steel must be clean, so it is important that it does not pick up oil or grease from the drive chains. Thus there is a need for precise lubrication; neither so much that excess can transfer onto the steel nor so little that the chain becomes dry and fails prematurely.

In reality the mill operators found access to the chain for maintenance difficult due to the height of the tower. As a result, maintenance schedules tended to become fitful and reactive, which led to the original chains suffering from issues of ‘kinking’ due to poor lubrication penetration.

This was followed by failed links due to wear and/or overload. Inspection of the chain after it had been in use for some time indicated that it also suffered from uneven wear rates, which caused further overload on the remaining chains.

Eventually the mill called in Tsubaki, to see if its engineering expertise and advanced chain products could improve the situation.

Transmission chain has been serving industry for decades. For 100 years Tsubakimoto Chain Co. has been a leader in R&D, having made significant advances in the technology designed to address demanding and unusual applications. It also steadily advances its chain manufacturing processes to ensure quality and competitiveness.

The company explains that rather than simply pursuing cost reductions, it believes its primary goal is to differentiate Tsubaki by forward-thinking investment and a focus on product development. As a result, it has a number of innovative chain technologies such as lube-free, corrosion resistant and harsh environment products.

After a visit to the steel mill, Tsubaki recommended replacing the existing chain with some of its standard BS chain, GT4 Winner. The technology within these has been refined through several generations of design. The G8 RS Roller Chain is the company’s standard line that meets the needs of most applications.

These eighth-generation designs offer a 20% improvement in service life over the previous designs; a special corrosion suppressing oil is applied to the chain in the final stage of manufacture to inhibit rust and improve durability. Developed in-house, this oil does not leave a sticky residue on the chain surface, which could otherwise transfer to the sheet steel.

The new G8 Super (Heavy Duty) Drive Chain is aimed at applications requiring the movement of large loads at low speeds. This chain provides great strength as a result of a new heat-treatment process, thicker material, and innovative geometry while remaining the same size as the standard type of chain.

Because the looper tower needs very long lengths of chain, the mill had experienced problems with uneven chain length due to wear and stretch. Tsubaki has addressed similar issues previously and has developed its Match and Tag service, which guarantees a maximum chain length difference of 0.50mm independent of the total chain length, so that they can be used in pairs or larger groups.

Tsubaki also fitted new sprockets made to the same high specification, supplied the chain in super long lengths to reduce fitting time and agreed to provide annual monitoring of the chain.

As a result of fitting Tsubaki chain, the looper tower now runs continuously with ultra reliability, requiring little maintenance beyond the annual inspection and keeping the steel’s surface clean for effective annealing.

Similar articles

More from Tsubakimoto UK Ltd

- Conveyor chain life doubled with bespoke solution 28th March 2019

- Extracting the benefits of customised chain solutions 28th January 2019

- Chain wear indicators now come in large sizes 28th November 2018

- Service to ensure paired chains are the same length 16th October 2018

Write a comment

No comments