Embedded intelligence in readiness for Industry 4.0

Smart plastics could be the future of Industry 4.0 applications according to motion plastics specialist, igus. The evolution of its cable, energy chain and linear bearing products embeds intelligence into its motion plastics via the addition of sensing, monitoring and communications. Using smart plastics, customers can increase plant availability, maximise up-time and reduce costs through condition monitoring and predictive maintenance.

igus motion plastics are used throughout industry and everyday life in moving applications. Its engineering plastics are self-lubricating and maintenance-free. For dynamic applications, this results in more reliable and cost effective solutions which also defy rain, salt and extreme temperatures, as well as being resistant to UV, oil and chemicals. Thanks to extensive testing in its 2,750m² test lab in Cologne, igus is able to accurately predict the service life of its motion plastics, offering reliability guarantees.

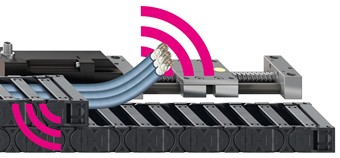

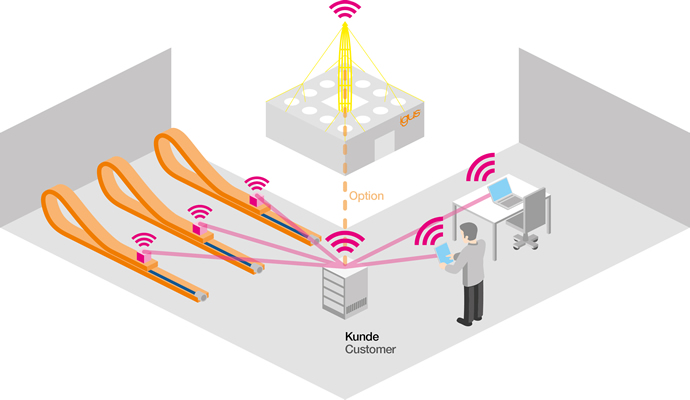

According to igus, smart plastics represent the next step for motion plastics - adding intelligence and networking to enable Industry 4.0 smart factories of the future via automated condition monitoring and predictive maintenance, improving reliability and reducing costs. Intelligent cables, energy chains and linear guides constantly monitor themselves, providing performance data and early warning of critical wear. isense encompasses a range of sensing technologies and monitoring modules, while networking with the igus Communication Module (icom) provides direct integration with the customer’s IT infrastructure or the igus data cloud.

“isense continuously monitors the service life of your e-chain, cable or linear guide via measurements and calculations using the parameters of your system,” said Matthew Aldridge, Managing Director, igus. “These measurements are referenced against aggregated test data from the igus test laboratory to reliably predict smooth functioning in real world operation. Alerts are sent when measured values exceed thresholds, allowing timely maintenance or replacement.”

Data can also be optionally shared with the igus data centre, opening up additional possibilities for customised service life calculation and optimisation of business processes, including maintenance commissioning, spare parts ordering and just-in-time delivery. In this way, electronic intelligence lowers maintenance costs even further and increases plant availability.

Similar articles

More from igus UK Limited

- From garage business to world leader: igus founders celebrate 90th birthday 22nd June 2021

- VOTW - Metal out plastic in! 10th June 2021

- igus robot works alongside agri-tech startup 18th May 2021

- Tribo-polymers increase machine service life and efficiency 10th May 2021

Write a comment

No comments