Space system improves time and costs with 3D printing

Metal 3D printing technology has been developed to help space systems reduce time and costs.

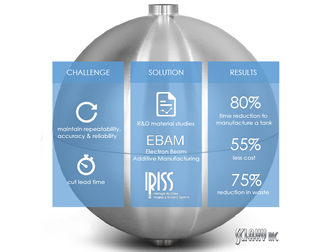

Sciaky’s Electron Beam Additive Manufacturing (EBAM) technology helped Lockheed Martin Space Systems reduce production time, material waste and overall costs for producing titanium propellant tanks for satellites.

The technology can be utilized anywhere in the product life cycle- from rapid prototypes and production parts to repair and remanufacturing applications, and the technology used allows the part production to be replicated according to the same established parameters (i.e. geometry, material properties and material composition) from the first part to the last.

Lockheed Martin Space Systems and Sciaky began to work together in 2012 with a materials research and development initiative to investigate the performance of Ti-6Al-4V (titanium) with its satellite propellant tank. After testing Lockheed and Sciaky were able to identify a process that would reduce time, waste and costs of the part as compared to the traditional forging method.

"The Space Systems business area was looking for ways to reduce costs on the satellite parts, while also maintaining product quality,” stated Marilyn A. Hewson, Chairman, President and CEO of Lockheed Martin.

Aiming to develop titanium propellant tanks that can be 3-D printed through the use of their electron beam additive manufacturing process, the result was a tank with an 80% reduction in the amount of time needed to manufacture it, a 75% reduction in waste, and a 55% reduction in cost.

Sciaky's EBAM systems can produce parts ranging from 8" (203mm) to 19m (5.79m) in length, but can also manufacture smaller and larger parts, depending on the application. EBAM is also has gross deposition rates ranging from 7 to 20lbs. (3.18 to 9.07kg) of metal per hour. Plus, with a dual wirefeed option, you can combine two different metal alloys into a single melt pool to create "custom alloy" parts or ingots.

Similar articles

More from Lockheed Martin UK Holdings Ltd

- Space system improves time and costs with 3D printing 12th July 2016

ed.jpg)

Write a comment

No comments