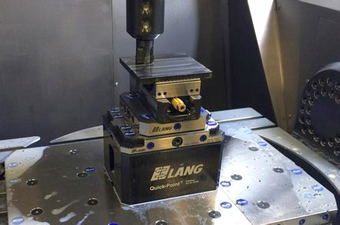

Multi-clamping system saves time during change-over

A multi-clamping system that can be retrofitted to almost all machine tool’s table has been released by Thame Workholding. The Lang Quick-Point multi-clamping system save stime during the change-over of vices, fixtures and workpieces.

The mechanical, multi-clamping grid plate system allows up to four vices or fixtures per plate to be clamped and released using only one actuation screw, making it possible to reduce and divide set-up time by a factor of four, increasing the ease of operations. The various ways to equip the machine table by aligning different sized grid plates is almost unlimited and the plates work in any orientation. This will help machine shops achieve maximum space and flexibility on the bed or table of any machining centre or milling machine.

Two grid plate sizes are available with an array of four by four or two by four locations, measuring 384x384 and 192x384mm respectively. The Quick-Point plates can be placed in any configuration on the machine tool’s bed or table to provide multiple locations for fixtures and direct component location, as well as the fitting of the Lang Makro-Grip system that requires just 3mm of clamping depth on a square or rectangular workpiece to provide maximum holding power at minimum clamping force. Advantages include material savings due to minimal wastage and unrestricted access for five-face machining that facilitates the use of short cutting tools.

Maurice Day, Sales Director, Thame Workholding, says: “The Quick-Point multi-clamping grid plate system will increase the flexibility of any machining centre, as the worktable effectively becomes a large zero-point reference. At just 27mm high it is one of the lowest systems in the world, which minimises the reduction in the distance between the spindle nose and the workpiece. With exceptional positional repeatability and accuracy the system can drive up manufacturing efficiency with less time spent loading and unloading more parts can be machined per hour.”

Similar articles

More from Thame Workholding

- Multi-clamping system saves time during change-over 5th August 2015

- Trueborer is quick and accurate 17th February 2015

- Manufacturers under pressure should consider vacuum technology 10th February 2015

- Thame turns up the efficiency with Powerpull 3rd October 2014

ed.jpg)

Write a comment

No comments