Automotive aluminium meets its match in new milling platform

Automotive aluminium may have met its match in the form of the new KBDM face milling platform from Kennametal. Replacing a head gasket on an internal combustion engine is a smooth, flat surface on both the cylinder head and block which is needed for proper operation. No one understands this better than automakers, who strive for predictable, controlled surface finishes and high production output, together with maximum tool life and the lowest tooling cost per machined component.

Many machinists might think, ‘What´s the big deal? Aluminium is one of the easiest materials around.’ And while that is certainly true of the ubiquitous 6061-T6, nothing could be further from the truth when it comes to the aluminium alloys used in automotive applications. Grades 319 and 390, for example, are readily cast into the complex shapes needed for engine blocks, pistons, heads, pulleys, and similar parts, but due to their high silicon content—easily 20-30 times that of 6061—they´re like cutting sand.

Fortunately for those charged with machining these abrasive metals, there´s a better alternative than carbide cutting tools, one that produces mirror finishes and produces tens of thousands of parts per edge.

Senior Global Product Manager for Indexable Milling at Kennametal, Tim Marshall said: “Finishes of 2-3μm Ra are easily obtainable, as is tool life between indexing of 40,000 engine blocks, cylinder heads, and other automotive components.”

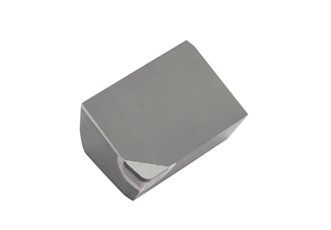

Marshall continued: “This new face milling platform uses a fine-pitch aluminium body with wedge-style clamps and adjustable pockets. A variety of Polycrystalline Diamond (PCD) inserts are available, from mini-tips for light finishing cuts to full face wipers, standard cartridge inserts, and 12.7mm (0.5”) axial cutters for heavy roughing and shoulder cutting.”

He´s talking about the KBDM PCD face milling system from Kennametal. Designed for high-volume machining, the KBDM is stocked in standard sizes of 63-200mm (2.5-8.0”), although quick to point out the company´s custom solution capabilities. “We can offer cutters up to 550mm (21.5”) in diameter. This allows customers to machine very large components in a single pass. We also have options for integral shank bodies, HSK mounting, left hand cutter rotation, as well as special edge preps and nose radii.”

There´s more to the KBDM than a robust body design, however. Since automakers often create their own proprietary aluminium alloys, Kennametal has developed two PCD grades to complement it: KD1400 uses small diamond grains and offers excellent chipping resistance and good wear attributes, while KD1425 uses large diamond grains, giving it excellent abrasion resistance and thermal stability but only slightly lower performance where chipping is a concern.

Both are capable of very high cutting parameters—depending on the alloy and setup rigidity, Kennametal recommends an initial cutting speed of 1000m/min (3280ft/min) and feedrates of 0.01mm (0.004”) per tooth, although substantially higher values are possible.

Marshall continued: “A major machine builder conducted cutting tests for us against several competitive solutions. Using a 24-tooth, 150mm (6.0”) diameter face mill at 80% radial engagement and 1mm (0.04”) axial DOC, we ran at a federate of 0.15mm (0.006”) IPT and 2926 m/min (9600ft/min) surface speed. This comes out to 6112rpm, with a table feed of 22,350mm/m (880IPM). It was really moving. Even so, the KBDM produced a 14.7Ra surface finish, several points better than the other cutting tools.”

Marshall recommended pre-setting the KBDM offline using an optical or video style pre-setter. A small amount of lubricant should be applied to the adjustment and locking screws, and also the wedge side of the pocket. Turn the axial adjustment screw until the insert is 0.010 - 0.015mm (0.0004 - 0.0006”) below the final set height, tighten the locking screws to 3.5Nm/lb. (31”/lb.)—don´t over tighten—then adjust each insert to its final height position.

Marshall concluded: “It´s simple to set up. You can easily get everything within a couple microns. That's one of the keys to successful face milling, not only for proper balance at high spindle speeds but also for achieving the desired surface finish—when you're finishing a deck face on a block or head, both are critical.”

Similar articles

More from Kennametal U.K. Ltd.

- Decades of experience brings happiness through hydraulics 7th March 2018

- Let's make turrets terrific! 6th February 2018

- Latest machining tool shows its metal 16th November 2016

- The drive to succeed 7th November 2016

ed.jpg)

Write a comment

No comments