Kennametal U.K. Ltd.

Address:

Pensnett Trading Estate

Kingswinford

West Midlands

DY6 7NP

United Kingdom

Kingswinford

West Midlands

DY6 7NP

United Kingdom

Kennametal U.K. Ltd. articles

Displaying 1 - 20 of 26

Decades of experience brings happiness through hydraulics

Solving the age-long problem of tool stability when drilling in deep cavities alongside tall shoulders, and past bulky fixtures, Kennametal has the answer. Reaching deep inside a workpiece to drill holes can be a real bear. You´ve tried taper length and aircraft drills, but even those made of solid carbide are apt to wander when hanging out of the chuck unsupported. Maybe you´ve combatted the problem with special extended-reach drill holders, although these are not only expensive, but limited to specific fixed lengths.

7th March 2018

Let's make turrets terrific!

Are you still using standard lathe tooling? Well it is time for a change, which will be a big change, but a quick and painless one. As machine tools become increasingly complex and the need to produce parts in less time grows, CNC lathe owners and managers must look to the latest technologies if they´re to improve shop floor efficiency.

6th February 2018

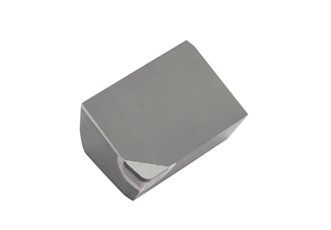

Latest machining tool shows its metal

Helping to tackle the toughest cast iron applications, the Kennametal’s Mill 16 comes with a wedge-style lamping system, numbered pockets and inserts and an open pocket design to increase chip flow in heavy roughing. Iron is the most abundant element on earth by mass. For over 25 centuries it´s been used to plough fields, build bridges, cook food, and wage war.

16th November 2016

Automotive aluminium meets its match in new milling platform

Automotive aluminium may have met its match in the form of the new KBDM face milling platform from Kennametal. Replacing a head gasket on an internal combustion engine is a smooth, flat surface on both the cylinder head and block which is needed for proper operation. No one understands this better than automakers, who strive for predictable, controlled surface finishes and high production output, together with maximum tool life and the lowest tooling cost per machined component.

24th October 2016

Set-up time reduction sees a new twist

Shortening set-up time, increasing productivity and generally improving the bottom line for job shops and large manufacturers alike are easily achievable through quick-change modular tooling. The KM system from Kennametal, Latrobe, can provide high clamping strength and consistent accuracy in both spindle-mounted and static tooling applications.

12th October 2016

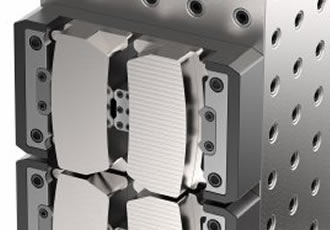

The next level in modular milling tools

Taking a step forward, Kennametal’s modular milling tools and its DUO-λOCK DUO-LOCK modular end mills fit a wide variety of tool holders and adapters, including the KM4X platform. Back in 2014, Kennametal announced a technology partnership with Haimer for the development of a modular cutting tooling system.

28th September 2016

Indiana Evolution

A job shop in the Midwestern US State of Indiana cuts insert costs in half and triples tool life with Beyond Evolution grooving and cut-off tools from Kennametal The Chip Breaking Effect: Direct delivery of cutting fluid to the work zone together with a variety of application-specific chipbreakers provides the Beyond Evolution grooving and cut-off system robust chip control while substantially extending tool life.

18th May 2016

Kennametal Recognized with Bosch Global Supplier Award

Kennametal Inc announced that it has been awarded the Bosch Global Supplier Award 2015 from Robert Bosch GmbH. The biannual award recognizes outstanding performance in the manufacture and supply of products or services – notably in the areas of quality, costs, logistics and innovations.

14th September 2015

Kennametal joins AMRC

Kennametal Inc announced that it entered into a partnership with the University of Sheffield Advanced Manufacturing Research Centre (AMRC) with Boeing.

21st May 2015

Kennametal and Haimer Announce Joint Technology Agreement on DUO-LOCK Modular Interface

In an agreement signed earlier this year, Kennametal Inc. and Haimer GmbH have agreed to a revolutionary joint technology partnership and development cooperation for modular cutting tool systems. The agreement involves a significant cross-license model and long-term partnership. "This agreement is a perfect fit because it illustrates both Haimer and Kennametal as leaders in high-end innovative technologies for world manufacturing," states Carlos Cardoso, chairman, president and CEO, Kennametal Inc.

21st October 2014

Full-Range Stellram Portfolio from Kennametal Expands Pathways to Metalcutting Excellence

Late last year, Kennametal finalized its acquisition of the tungsten materials business from Allegheny Technologies Inc., including the full line of Stellram metalworking tools (formerly ATI Stellram). Now the full platform of Stellram products – with solutions specifically tailored to support energy, aerospace, transportation and other vital industries -- are available as part of the Kennametal portfolio.

16th October 2014

New Beyond EADE Solid Ceramic Endmills from Kennametal

Industry first shows outstanding reductions machining turbine blades and other energy/aerospace componentsNew 6-flute Beyond KYS40 solid ceramic end mill from Kennametal. Perhaps the most basic assumption in machining is that cutting high-strength materials takes higher-strength tools. Proprietary nickel-based alloys used in gas and steam turbines, for example, are among the world´s strongest materials, continually being developed to allow power plants to run at much higher temperatures.

7th May 2013