Set-up time reduction sees a new twist

Shortening set-up time, increasing productivity and generally improving the bottom line for job shops and large manufacturers alike are easily achievable through quick-change modular tooling. The KM system from Kennametal, Latrobe, can provide high clamping strength and consistent accuracy in both spindle-mounted and static tooling applications.

Boeing came to Kennametal with a request for a heavy-duty spindle connection capable of outperforming traditional CAT and BT-style adapters, the tooling engineers turned to this robust platform as a starting point. The result was a 100mm spindle connection with four ball tracks instead of two and up to 40% greater clamping force than comparably-sized KM tooling.

That was 15 years ago. KM continues to thrive, and was adopted in 2008 by the International Organisation for Standardisation (ISO) as ISO standard 26622. The original Boeing-inspired design has been renamed as well, and marketed for the past several years as KM4X100, a spindle platform popular with machine builders such as Fives Group, Mitsui Seiki, Stama, and others, as well as those machine shops looking for superior rigidity in demanding machining conditions.

Kennametal has announced the KM4X tooling family has gained a 63mm sibling, one aimed at a broader machine tool platform and therefore greater availability to the machining community.

Kennametal Global Product Manager, Tooling Systems, Bill Redman said: “Just as we did with Boeing, we challenged ourselves to make a great solution even better.”

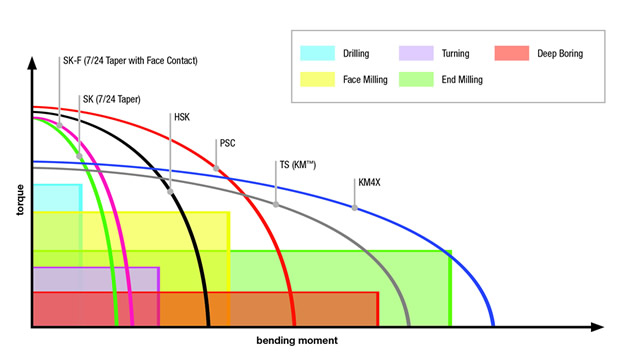

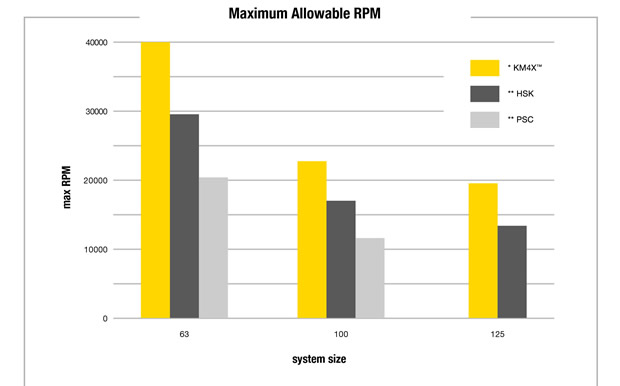

Redman added: “The clamping strength, bending stiffness, and RPM capabilities of the KM4X63 are dramatically higher than virtually any other connection out there.”

Redman and others on the product management and engineering team recently approached a number of machine builders to ask for opinions on the initial KM4X product offering. Based on that feedback, Kennametal continues to expand the portfolio—the KM4X lineup now includes shrink fit toolholders, HydroForce hydraulic chucks, TG and ER collet chucks, and a variety of other spindle tooling, clamping units, and modular adapters, with more on the way.

Redman commented: “By the end of 2016, we're going to add roughly 30 new line items, most of which will be extensions in the 80-200mm range, and centreline turning tools to support mill-turn applications.”

He added: “We´ve found that, because of KM4X´s extreme rigidity, we can greatly increase gage lengths. This means our customers can reach much farther without having to buy a special tool, something that´s especially important with 5-axis machining—they can basically add on whatever extension length is needed and off they go, in both static or rotating applications. We're pretty excited about that.”

One example of this is a 674mm gage length (26.54”) KM4X boring bar that will be displayed on an Integrex i-400 in the Mazak booth at this year´s IMTS. “KM4X63 has a maximum bending moment of 2,100Nm (1548ft.) and, depending on the machine, clamping force of 36-58Kn (8093-13038lb.)” he said. “It´s the strongest connection available in this size range, period.

Redman said it is also fasted, the KM4X63 comes ‘out of the box’ capable to 38,000rpm, which is higher than HSK-A and dramatically faster than competing brands of spindle tooling.

For those shops on the fence about spindle tooling and quick-change, Redman offers the following advice: “There´s nothing worse than going into a shop that just bought a $500,000 machining centre or lathe and then discovers they should have opted for a different tooling platform. We as tooling providers have an obligation to educate customers, and get them thinking about what they´re trying to accomplish—whether they need high spindle speeds for an aluminium or die-mould application, or greater low-end torque for titanium and HRSA machining.

Concluding, Redman said: “The majority of tooling systems out there can accommodate one of these things, but not both. We feel KM4X provides a competitive advantage no matter what you´re cutting.”

Similar articles

More from Kennametal U.K. Ltd.

- Decades of experience brings happiness through hydraulics 7th March 2018

- Let's make turrets terrific! 6th February 2018

- Latest machining tool shows its metal 16th November 2016

- The drive to succeed 7th November 2016

Write a comment

No comments