Automated sawing from engineering component supplier

Acquiring two automated pivoting-bow bandsaws from Kasto, a UK provider of light engineering components, Stourbridge-based Tasman Industries, saw the most recent one delivered in December 2016. They have transformed the efficiency with which the firm cuts bar material in a vast array of metal types and sizes into large batches of up to several thousands. For smaller runs, say 50-off, it relies partly on a similar, semi-automatic saw installed earlier last year by the same supplier.

Tasman specialises in supplying shaft keys, keysteel, shaft collars, taper and slotted pins, precision dowel pins, screws and many more products in sizes spanning a few square millimetres in cross section up to 125mm diameter, 100x50x75mm square. Materials range from steels, including stainless, through nickel alloys and titanium to copper alloys, aluminium bronze, phosphor bronze and brass.

The company oversees a complex manufacturing and distribution business involving sourcing raw material and products from all over the world and shipping it to 3,500 customers, 800 of which are active in any given month. Ranging from blue chip multinationals to individuals repairing their lawn mower, they are mainly in the UK but can be found as far afield as New Zealand.

Complicating these activities is the fact that only half of output is standard, the remainder being bespoke specials supplied to customer specification. They require a combination of milling, turning, grinding, laser cutting, heat treating and plating, carried out by around 1,200 subcontractors, only half of which are in the UK.

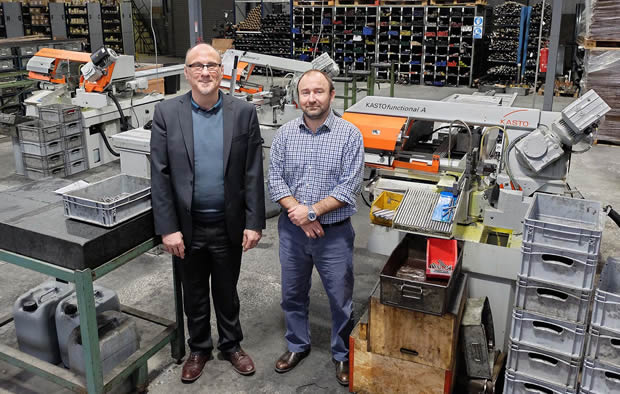

The only machining performed at Tasman’s warehouse in the West Midlands is straight and mitre cutting of 200 tonnes of bar material per year. The backbone of this function are two KASTOfunctional A pivoting-bow, automatic bandsaws and a KASTOfunctional U semi-automatic model.

They are of solid construction with a robust, torsion-free welded base, capable of cutting material to a maximum of 260mm round / square. Stock can be mitre-cut to the left at up to 45° and to the right at up to 60°.

John Bairner commented: “We tried moving to automatic sawing a few years ago with the purchase of a circular saw from another manufacturer, but the blade kept breaking, the hydraulics leaked and overall it was not a good experience.

“We went back to using a pair of semi-automatic bandsaws, of which we still use one, but could see the benefits of automation for longer runs.

“So in 2014 we decided to go down the automatic bandsaw route and installed the first KASTOfunctional A with a roller infeed table, having been impressed with a demonstration at the company’s Milton Keynes showroom.

“The machine proved so accurate, reliable and productive that we went for the semi-automatic U version during the first half of 2016 and a second fully automatic model at the end of the year.”

A facet of the bandsaws that impresses Bairner is that the material is fed accurately by a ballscrew drive, as used for axis positioning on mainstream machine tools, rather than via a leadscrew or a hydraulic cylinder.

Another feature was the user-friendliness of the Kasto touch-screen control, which allows easy programming of the next cutting job. An in-built database saves time by automatically selecting the correct band speed and rate of downfeed to suit the type and size of material to be cut.

As cutting volumes increase, buying a bundle clamp for one of the KASTOfunctional will be considered, as to increase sawing efficiency further when processing bar of smaller cross section. This could happen sooner rather than later, as at the start of 2017 Tasman introduced a subcontract cutting service whereby it will saw to length and mitre cut stock for other companies in the Midlands.

Similar articles

More from KASTO Ltd

- Large distribution centre built for steel stockholder 19th November 2018

- Precision double mitre cutting bandsaw 7th September 2018

- Robotic handling raises sawing productivity 15th May 2018

- New circular sawing machine significantly speeds up deliveries 8th May 2018

ed.jpg)

Write a comment

No comments