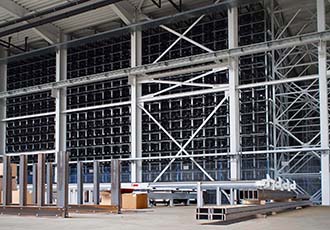

Large distribution centre built for steel stockholder

To streamline and speed deliveries of long stock to customers, a Unicompact high-performance storage and distribution system from Kasto has been installed in a new, purpose-built unit in Ellwangen operated by Friedrich Kicherer, one of the largest steel stockholders in Germany. Three KASTOwin F bandsaws have been integrated into the system.

Eberhard Frick, Managing Partner of Kicherer, commented: “We had a great range of materials but it was taking far too long to load the lorries. We needed something that was significantly faster than our existing stacking cradle system.

“To optimise material flow as well as increase storage capacity, we decided to build a second steel centre and approached two potential suppliers of bar storage warehouses, one being Kasto with which we have had a successful relationship for more than 20 years."

Employing more than 350 staff, Kicherer ships 210,000 tonnes of steel per year. Six pre-existing automatic storage systems from Kasto and 44 cranes in the original steel centre optimise the operation. The first Kasto store was installed in 1995, which over the years was supplemented by racking systems for tubes, stacking cradles for structural steel profiles, angles and boiler tubes, and a Uniline 3.0 sheet metal store with 610 cassettes. These investments were mostly driven by the objective of expanding the range and providing faster deliveries

Another board member, Eberhard Frick's brother, Hans-Jörg, explained: "At the moment, a lorry drives through seven areas for loading. If everything goes well, this takes 75 minutes. The objective was to reduce the time to less than an hour but in practice it has been shortened to just 15 minutes.”

Kasto was selected for the latest project to supply the new bar storage system with central loading station linked to the stockholder's IT system. The solution is based on a 115m long, 15m high, automatic honeycomb storage system with space for more than 10,000 cassettes. Each can accommodate material up to six metres in length and carry 3.4 tonnes. Fast storage and retrieval of stock is achieved with five cranes travelling at up to 180m/min along three aisles of racking.

To transport picked materials to the loading station automatically, Kasto has installed two manipulators on separate rails. From these, the bar stock travels to one of 25 loading stations via a conveyor. A station with a packaging machine is provided for stretch film wrapping. The IT departments at Kicherer and Kasto have jointly modelled all components of the new logistics system in unified software within the KASTOlogic warehouse management system.

Kicherer tracks its steel profiles through the store using QR codes. Every bundle that has been picked is scanned again on loading and its status is automatically entered into the material requirements planning software for full traceability.

Similar articles

More from KASTO Ltd

- Large distribution centre built for steel stockholder 19th November 2018

- Precision double mitre cutting bandsaw 7th September 2018

- Robotic handling raises sawing productivity 15th May 2018

- New circular sawing machine significantly speeds up deliveries 8th May 2018

Write a comment

No comments