Wogaard Coolant Saver offers a win:win for visitors at Advanced Engineering 2015

Visitors to the Wogaard stand (B87a) at Advanced Engineering 2015 will not only have the opportunity to see the award-winning (which award?) Coolant Saver in action; they will also get the chance to enter a prize draw. By simply dropping their business card into a bowl on the stand one lucky visitor will win the celebration ‘Millennium’ Wogaard Coolant Saver that marks the fact that over 1,000 of the units have been produced. Needs commas, or something to break down the sentence length.

Director of Sales, Jason Hutt, explains: “Manufacturers and precision engineering subcontractors alike have embraced the multifaceted benefits offered by the Coolant Saver. Not only can machine shops directly save a significant amount of money by recovering any neat oil or water miscible coolant dragged out of the machine tool by the swarf, they can also save on material handling and waste disposal.”

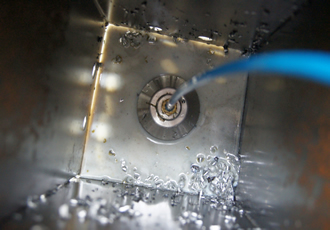

The simplistic design and execution of the Wogaard Coolant Saver belies the potential benefits it can provide to manufacturing companies. Using very few component elements it efficiently collects the cutting fluid which is normally dragged out of the machine tool by the swarf that is evacuated by the automatic chip conveyor or swarf auger and wasted. The cutting fluid is reclaimed by siphoning it from the chip-container and returning it to the machine tools main coolant tank for reuse.

It consists of a stainless steel vacuum cup that is simply placed on the bottom surface of the chip container, and a Venturi-unit that branches off the pipe supplying coolant or cutting fluid to the CNC machine tools spindle or coolant nozzles. This generates the vacuum required to return the collected liquid back to the CNC machine’s main coolant reservoir. The vacuum cup is fitted with a filter mesh to prevent chips and small debris from entering the system.

With so few elements and no moving parts the Wogaard Coolant Saver is easy to install and is virtually maintenance free. Driven by the machine tool’s coolant pump no external energy source is required, so it benefits from being devoid of any ongoing operational costs. Rewrite.

Another business consideration that comes to the fore is the positive environmental impact achieved by the Coolant Saver states Jason Hutt. Not a sentence. “We promote our philosophy of reduce, reuse and recycle where possible. As businesses push for ISO 14001 we know the Coolant Saver can make a dramatic difference to their goal of a greener operation for a very modest outlay. We have actual customer examples highlighting not just the return on investment, but also the carbon footprint reduction achieved. It is a much more cost-effective solution than the alternative methods of reclaiming coolant/oil from chips such as swarf spinning centrifuges.”

Similar articles

More from Wogaard Limited

- Leave no stone left unturned with this oil saver 2nd March 2017

- Technical partnership based on trusted values 27th September 2016

- Wogaard Coolant Saver offers a win:win for visitors at Advanced Engineering 2015 10th September 2015

- Coolant units proves its worth on shop floor 15th August 2014

Write a comment

No comments