Design processes and software tools to be revealed at formnext

Presenting at this year’s formnext, in Frankfurt, Altair will be showcasing the latest versions of its simulation software suite HyperWorks 14.0, concept design and optimisation tools solidThinking Evolve as well as Inspire 2016, highlighting new design processes for the development and manufacturing of innovative products.

In addition, Altair and its customers will also present their projects developed with Altair’s software solutions at the formnext conference from 15th-18th November, hosted by TCT.

Highlights at the booth will be Altair's Simulation-driven Innovation approach, the development process chain of the Airbus APWorks’ Light Rider, the world's first prototype of a 3D printed electric motorcycle, the 3D printed antenna bracket by RUAG Space and the entire development and manufacturing processes of a cast aluminium component, developed jointly with Altair’s partners HBM nCode and voxeljet.

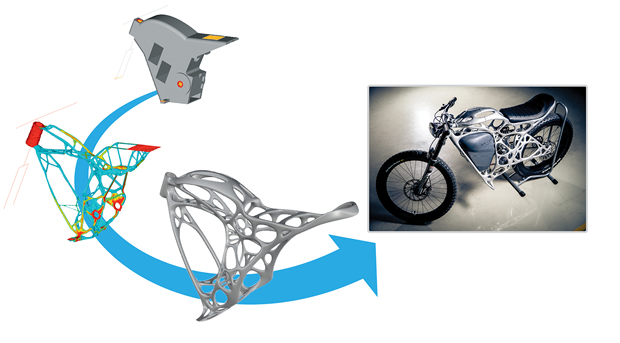

The frame design of the Airbus APWorks’ Light Rider that will be displayed at the event is an excellent example of the symbiosis of topology optimisation and additive manufacturing. Its structure is based on optimisation results generated with Altair's OptiStruct technology, supported by HyperMesh for pre-processing tasks such as meshing, and HyperView for post-processing the analysis results. All products are part of the HyperWorks CAE simulation suite.

Applying a typical topology optimisation OptiStruct run,the APWorks engineers first defined the design space (areas where the optimisation technology can and cannot remove material, such as fixing points or access holes) and applied general loads and boundary conditions.The optimisation software then created a design proposal that fulfilled the frame’s structural requirements, by generating highly innovative geometries.

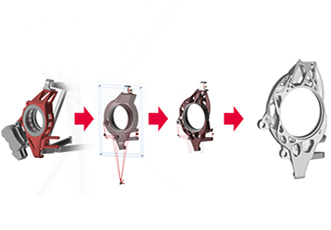

The cast aluminium component also to be displayed at the booth was designed and optimised with Inspire, then nCode DesignLife was applied to conduct a fatigue analysis and finally solidThinking's Click2Cast software was used for a casting simulation. The created design resulted in a casting mould, 3D-printed by voxeljet. This process ensured that the component benefited from all of the positive characteristics 3D printing and casting offer.

“We are very much looking forward to presenting our solutions, including our Simulation-driven Innovation approach at formnext," said Mirko Bromberger, Director Marketing and Additive Manufacturing Strategies at Altair Engineering.

Bromberger added: “Additive manufacturing (AM) is making headlines across industry as companies discover and take advantage of the inherent flexibility as well as the potential weight advantages the method offers, when combined with design optimisation techniques. As we will present with the example of the Light Rider, when topology optimisation and additive manufacturing are combined, it is possible to produce a structure that is lighter and stiffer than a traditionally manufactured part. The visitors of formnext can expect a very broad and informative program, highlighting solutions for the different production and engineering disciplines.”

Similar articles

More from Altair Engineering

- Altair Feko WinProp to be exhibited at EuCAP 2019 in Krakow 20th March 2019

- Design poised to transform product development 11th September 2018

- 2018 Global Altair Technology Conference keynotes announced 23rd July 2018

- Flow simulator software for engine system modelling 18th July 2018

Write a comment

No comments