Scottish Canal’s Falkirk Wheel receives a visit

AEMT members were able to gain an exclusive audience with the Principal M&E Engineer for the Falkirk wheel, at the Scotland meeting this year. After being guided through the more technical aspects of the engineering behind the wheel and the connected canals, members were taken on a tour of the wheel’s engine and maintenance rooms.

Steven Berry B.Sc MIET is a contented, and enthusiastic person, whose passion for engineering is infectious. His occupation takes him up and down the Scottish canals, looking after the mechanical and electrical aspects – in particular the Falkirk Wheel, Kelpies, and Helix Park. Much of the work includes power and control systems, mechanical and hydraulic upgrades, and energy saving equipment.

It’s clear that he takes great pride in the work he does for Scottish canals. With the Falkirk Wheel being the central aspect of an £85m re-investment in the Scotland’s inland waterways – he has quite a lot to be proud of. The canals are dominantly a tourist attraction these days, a far cry from the toil they received at the turn of the century. With around 400,000 visitors a year, it brings a crowd – and what a brilliant location to show off the engineering capabilities of Great Britain.

The Wheel

Opened in 2002 as part of the Millennium Link, a project that restored Scotland’s inland waterways to a navigable state for the first time since the 1960s The Wheel replaced a flight of 11 locks that once stepped the Union Canal down to the level of the Forth & Clyde over a distance of 1.5 kilometres and took more than a day to traverse. The Falkirk Wheel allows vessels to transit between the two waterways in just a few minutes.

While touring around the wheel in hard-hats and high-vis, members were approached by a keen member of the public, who presumably thought that we were the most reliable source for information on the wheel. In order to settle a wager with his partner he asked us to clarify the reason for the wheel’s unique design. Steven proudly deferred the question to us, after briefing us beforehand on the subject.

The unusual design of The Falkirk Wheel has been described using Scottish and marine architectural terms including a Celtic inspired double-headed axe, the spine of a fish, ribcage of a whale and the vast turning propellers of a Clydebank-built ship, so to answer the man’s question - aesthetics. Unfortunately, this was not the answer he was looking for – like most people he was sure there was some sort of an aerodynamic/engineering answer to the wings and he turned about with the skip from his step slightly down trodden.

Archimedes Principal

If a 200-tonne vessel approached the Wheel, glided onto a gondola and waited a few minutes for the wheel to effortlessly lift the 500 tonne gondola and vessel 35m, using only 1.5kw/h, you might question the principals behind the structure.

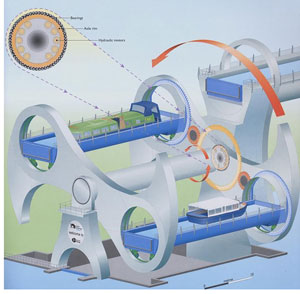

It took a combined effort between the British Waterways Board, and engineering consultants Arup, Butterley Engineering and RMJM to come up with the final design. The solution: when one of the structure’s gondolas is lowered, the opposite one rises, keeping the vast 1800 tonne boat lift in perfect balance as it carries canal barges up in a matter of minutes. The Wheel’s gondolas hold 500,000 litres of water each, and great care is taken to maintain the water levels on each side, thus balancing the weight on each arm.

According to Archimedes' principle, floating objects displace their own weight in water, so when the boat enters, the amount of water leaving the gondola weighs exactly the same as the boat. This is achieved by maintaining the water levels on each side to within a difference of 37mm (1.5”) using a site-wide computer control system comprising water level sensors, automated sluices and pumps.

Engine room

The area housing the machinery to drive the wheel is located in the final pillar of the aqueduct, and contains seven chambers connected by ladders. Access is by a door located at ground level or an entrance halfway up the tower, with a gantry crane to facilitate the installation of equipment.

The ground floor houses the transformers for powering the wheel. The first floor is a standby generator and switchgear; and the second floor houses a pair of hydraulic pumps that drive the hydraulic motors in the chamber above. Power is supplied directly to the axle with ten hydraulic motors, which also double as brakes. Connected to each motor is a 100:1 gear system to reduce the rotation speed.

Mechanism

Whilst the weight of the gondolas on the bearings is generally enough to rotate them, a gearing mechanism using three large identically sized gears connected by two smaller ones ensures that they turn at precisely the correct speed and remain correctly balanced.

Each end of the gondolas is supported on small wheels, which run on rails on the inside face of the 8m (26ft) diameter holes at the ends of the arms. The rotation is controlled by a train of gears: an alternating pattern of three 8m (26ft) diameter ring gears and two smaller idler gears, all with external teeth. The large central gear is fitted loosely over the axle at its machine-room end and fixed in place to prevent it from rotating. The two smaller gears are fixed to each of the arms of the wheel at its machine-room end.

When the motors rotate the central axle, the arms swing and the small gears engage the central gear, which results in the smaller gears rotating at a higher speed than the wheel, but in the same direction. The smaller gears engage the large ring gears at the end of the gondolas, driving them at the same speed as the wheel but in the opposite direction. This cancels the rotation due to the arms and keeps the gondolas stable and perfectly level.

Similar articles

More from AEMT (The Association of Electrical and Mechanical Trades)

- Mobile varnish lab is in fast lane to success 9th October 2019

- When it comes to electric motors what is best, new for old? 2nd May 2019

- What is IEC 60034-23 and how does it impact me? 28th January 2019

- Conference examines opportunities created by the Circular Economy 19th November 2018

Write a comment

No comments