Permanent Magnet Motors Come Of Age With Market Demands For Reduced Size, Weight And Improved Efficiency

11th March 2010

Source:

WEG ELECTRIC MOTORS (U.K.) LTD.

In all industrial sectors worldwide there is a general requirement to reduce the size and weight of equipment installations, at the same time improving their efficiency to cut operating costs and improve competitiveness. As the prime movers in all industries – and the major consumers of power - electric motors are naturally one of the main focuses for this development.

The standard 3-phase squirrel cage design of electric motor has been around for over a century, and with modern design and manufacturing processes, has probably achieved its optimum levels of performance. Moreover, the nature of the design means that achieving reductions in overall size, and improvements in power density for a given power output, are not really an option.

However, the squirrel cage design is very robust and reliable, and well proven in operation; it is also relatively inexpensive, which, up till now, has meant that more efficient new technology designs, such as permanent magnet motors, have not been widely adopted or applied.

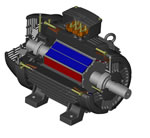

A new design of PM motor from WEG, the Wmagnet series, seeks to change this situation by offering a range of user benefits that bring PM motors into mainstream usage. The high efficiency WMagnet motors are designed for applications where constant torque, Iow vibration and low noise levels are required; typically elevators, compressors and conveyors. Because they can operate self-ventilated over a wide speed range, the motors are also ideal for use in applications where gearboxes need to be eliminated to save space.

The WMagnet series meets all the demands of modern manufacturing in terms of size and weight reduction and energy efficiency. They reduce size by up to 50%, weight by up to 36%, and deliver higher efficiencies (up to 97.5%) compared to equivalent size induction motors. In addition, they are, generally, at least one frame size or core length smaller than the equivalent induction motor, and in some cases can be two frame sizes smaller.

The major benefits of this are that the cooling system is reduced for the same torque/power ratio and, consequently, a reduction in the levels of noise from the fan coupled to the motor shaft.

WEG WMagnet motors are manufactured with high energy magnets (NdFeB) in their rotors; these deliver a significant reduction in energy losses compared to an induction motor, resulting in a lower temperature rise of the motor, generally, and increased operating life. In addition, as these energy (Joule) losses (RI2) account for a significant portion of total losses in induction motors, the PM motor delivers much higher efficiencies (up to 97.5%), easily exceeding the new harmonised IE (International Efficiency) standards: IE2, which comes into force July 2011, IE3, and also, importantly, attains IE4.

In addition to size, weight and operating advantages, a further benefit of WEG’s new PM motor is that it can operate on a wide speed range (up to 7,300 rpm in special cases) with constant torque. This operation is controlled by a version of WEG’s CFWO9 VFD, which has been specially developed for the Wmagnet range. The CFW09 employs its vector control technology to effectively drive the WMagnet from zero speed up to the field weakening region.

In one of the first field applications for the WMagnet motors. Buettner, a textile manufacturer, has reduced its annual power consumption by 33% and increased its machine utilisation by 80%. These twin gains have delivered substantial savings in production costs and have also improved the company’s profitability in a highly competitive global market.

Buettner is a Brazilian company that has been active in the textile sector for over 100- years. The company currently produces more than two- million bath towels each month for export to around 40 countries globally. The markets in which Buettner operates are highly competitive, and so the company is always looking for ways to increase efficiency and reduce costs.

It was these twin objectives in mind that Buettner purchased three WMagnet motors from WEG, in order to assess their performance on the company’s ring spinning machines. The subsequent outstanding success of the motors means that WMagnet motors are now set to become standard fitment on all of the 45 ring spinning machines operated by the company. “Our goal is to replace all of our standard induction machines with WEG WMagnet motors within three years,” said Aires Fantoni, Electrical Maintenance supervisor at Buettner.

The ring spinning machines are where raw cotton is transformed into threads of the desired thickness for each product, and is then wound onto spools. Previously, the machines operated with standard induction motors, at two discrete speeds; this meant that it was necessary to stop the machine for each gear change – a process that resulted in substantial losses in production time.

Seeking to overcome this problem, WMagnet motors were installed; the motors were controlled by WEG frequency inverters, which vary the machine revolutions from zero rpm to 1,800 rpm. “This arrangement means that our personnel no longer need to stop the machine to change gears,” said Aires Fontoni; “and we also benefit from the soft start provided by the WEG VFD, which reduces machine wear.”

The advantages of the motor replacement programme to Buttner are many. In addition to lower maintenance costs (practically zero), the variation of motor speed with constant torque and energy savings increases both the reliability and the performance of the company’s production line.

“We can deliver the same package of benefits with these motors across a wide range of applications – conveyors, compressors elevators – anywhere where variable speed with constant torque and high efficiency are required,” said Marek Lukaszczyk, European Marketing Manager for WEG. “As demonstrated by the Buettner application, the WMagnet motors are ideal for applications where eliminating a gearbox is essential; the motors can do this because they can operated self-ventilated over a wide speed range.”

However, the squirrel cage design is very robust and reliable, and well proven in operation; it is also relatively inexpensive, which, up till now, has meant that more efficient new technology designs, such as permanent magnet motors, have not been widely adopted or applied.

A new design of PM motor from WEG, the Wmagnet series, seeks to change this situation by offering a range of user benefits that bring PM motors into mainstream usage. The high efficiency WMagnet motors are designed for applications where constant torque, Iow vibration and low noise levels are required; typically elevators, compressors and conveyors. Because they can operate self-ventilated over a wide speed range, the motors are also ideal for use in applications where gearboxes need to be eliminated to save space.

The WMagnet series meets all the demands of modern manufacturing in terms of size and weight reduction and energy efficiency. They reduce size by up to 50%, weight by up to 36%, and deliver higher efficiencies (up to 97.5%) compared to equivalent size induction motors. In addition, they are, generally, at least one frame size or core length smaller than the equivalent induction motor, and in some cases can be two frame sizes smaller.

The major benefits of this are that the cooling system is reduced for the same torque/power ratio and, consequently, a reduction in the levels of noise from the fan coupled to the motor shaft.

WEG WMagnet motors are manufactured with high energy magnets (NdFeB) in their rotors; these deliver a significant reduction in energy losses compared to an induction motor, resulting in a lower temperature rise of the motor, generally, and increased operating life. In addition, as these energy (Joule) losses (RI2) account for a significant portion of total losses in induction motors, the PM motor delivers much higher efficiencies (up to 97.5%), easily exceeding the new harmonised IE (International Efficiency) standards: IE2, which comes into force July 2011, IE3, and also, importantly, attains IE4.

In addition to size, weight and operating advantages, a further benefit of WEG’s new PM motor is that it can operate on a wide speed range (up to 7,300 rpm in special cases) with constant torque. This operation is controlled by a version of WEG’s CFWO9 VFD, which has been specially developed for the Wmagnet range. The CFW09 employs its vector control technology to effectively drive the WMagnet from zero speed up to the field weakening region.

In one of the first field applications for the WMagnet motors. Buettner, a textile manufacturer, has reduced its annual power consumption by 33% and increased its machine utilisation by 80%. These twin gains have delivered substantial savings in production costs and have also improved the company’s profitability in a highly competitive global market.

Buettner is a Brazilian company that has been active in the textile sector for over 100- years. The company currently produces more than two- million bath towels each month for export to around 40 countries globally. The markets in which Buettner operates are highly competitive, and so the company is always looking for ways to increase efficiency and reduce costs.

It was these twin objectives in mind that Buettner purchased three WMagnet motors from WEG, in order to assess their performance on the company’s ring spinning machines. The subsequent outstanding success of the motors means that WMagnet motors are now set to become standard fitment on all of the 45 ring spinning machines operated by the company. “Our goal is to replace all of our standard induction machines with WEG WMagnet motors within three years,” said Aires Fantoni, Electrical Maintenance supervisor at Buettner.

The ring spinning machines are where raw cotton is transformed into threads of the desired thickness for each product, and is then wound onto spools. Previously, the machines operated with standard induction motors, at two discrete speeds; this meant that it was necessary to stop the machine for each gear change – a process that resulted in substantial losses in production time.

Seeking to overcome this problem, WMagnet motors were installed; the motors were controlled by WEG frequency inverters, which vary the machine revolutions from zero rpm to 1,800 rpm. “This arrangement means that our personnel no longer need to stop the machine to change gears,” said Aires Fontoni; “and we also benefit from the soft start provided by the WEG VFD, which reduces machine wear.”

The advantages of the motor replacement programme to Buttner are many. In addition to lower maintenance costs (practically zero), the variation of motor speed with constant torque and energy savings increases both the reliability and the performance of the company’s production line.

“We can deliver the same package of benefits with these motors across a wide range of applications – conveyors, compressors elevators – anywhere where variable speed with constant torque and high efficiency are required,” said Marek Lukaszczyk, European Marketing Manager for WEG. “As demonstrated by the Buettner application, the WMagnet motors are ideal for applications where eliminating a gearbox is essential; the motors can do this because they can operated self-ventilated over a wide speed range.”

Similar articles

More from WEG ELECTRIC MOTORS (U.K.) LTD.

- Helping engineers understand the new motor legislation 1st June 2021

- Transformer to help power Africa 19th April 2021

- Warehouse expansion for WEG Belgium 2nd March 2021

- Three equipment upgrades for agility and efficiency 1st February 2021

Write a comment

No comments