Modern drive concepts for closed-die forging presses

To significantly improve productivity and the energy efficiency of production equipment forging press line operators are calling for innovative solutions. The new Eumuco Hasenclever MT eccentric press series is the response from the SMS Group. The technical highlight in the series is seen in the Meer-Torque servo-drive concept that combines high energy, a very short cycle time and optimised energy efficiency.

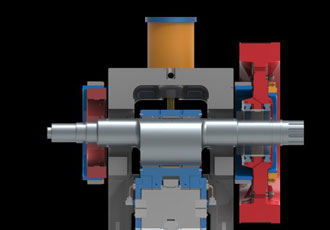

As is explained, two separate but synchronised drives shape the interplay of ram acceleration, ram deceleration and the allocation of forming energy. Contrary to conventional systems, the new concept avails itself of a continuously rotating but significantly smaller flywheel to accumulate the energy.

Moreover, the solution separates the ram movement from the allocation of forming energy. This reportedly allows a fusion of the advantages of servo-driven presses with those of conventional clutch-brake systems, namely extremely short die contact times due to very high ram speeds.

The drives provide an acceleration angle (120°) that is claimed to be around eight times larger than the acceleration angle of conventional clutch-brake drive systems (10 to 15°), which allows the required delivered torque to be around one eighth of a conventional drive system.

Similar articles

More from SMS Group

- Two converter shops aims to boost steel production in Vietnam 2nd August 2017

- Tolerance improvements with new straightening machine 25th July 2017

- Iranian steel plant commences production 24th July 2017

- Modern drive concepts for closed-die forging presses 3rd July 2017

Write a comment

No comments