UK launch of VERICUT Force announced

Set to launch the latest ‘physics-based’ toolpath optimisation module, CGTech the developer of VERICUTCNC Simulation, Verification and Optimisation software is releasing VERICUT Force, in the UK with a series of nationwide seminars. The Force Roadshow will be a series of half day seminars throughout June and July, kicking off at the Advanced Forming Research Centre, Scotland, on 14th June 2017.

A further 3 seminars will take place at KYOCERA Precision Tools, Wokingham (28th June), Nikken, Rotherham (4th July) and the Manufacturing Technology Centre, Coventry (6th July).

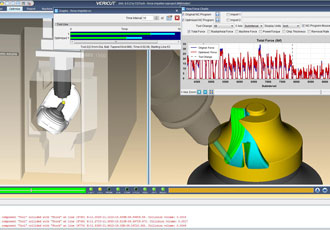

The Force module is a physics-based optimisation method that determines the maximum reliable feed rate for a given cutting condition based on four factors: force on the cutter, spindle power, maximum chip thickness, and maximum allowable feed rate. It calculates feed rates by analysing tool geometry and parameters, material properties of the stock and cutting tool, detailed cutting edge geometry, and VERICUT cut-by-cut contact conditions.

In this latest version, VERICUT 8.0.3, numerous enhancements have been added to Force, including new features for better control of entry/exit speeds, ‘clean-up’ feed rates, and tooling information has been re-arranged to be more intuitive.The updated Force module now receives input values directly from cloud-based tooling, and benefits from many new features that streamline optimisation setup.

By micro analysing the cutting conditions encountered by an NC Program, Force ensures NC programmes have optimal feed rates, and ideal chip thicknesses that do not exceed safe force or power limits.

Other new features include improved Charts display, which enables NC programmers and Mechanical Engineers to virtually ‘see’ and evaluate force, chip thickness, volume removal rates, and more in NC programmes before running on their CNC machine.

Force excels in difficult to machine materials, and especially complex multi-axis cuts such as 5-axis flank milling. CGTech Managing Director, Tony Shrewsbury, commented: “Force is based on the basics, it is easy to set up and really easy to use.” After materials have been characterised they can also be applied to a broad range of cutters and machines in other NC machining operation.

Initial users of this technology are already seeing productivity improvements of up to 50%. Each seminar will incorporate live software demonstrations and presentations to shine the spotlight on the features and benefits of Force.

Shrewsbury continued: “With these seminars we really want to demonstrate exactly what Force can do and the benefits of using it, including reduced development time, shorter cycle times, less process variation, longer machine life and improved part quality. It can also prevent tool breakage due to deflection.”

To register click here.

Similar articles

More from CGTech Ltd

- Achieving process optimisation through simulation 27th May 2020

- VERICUT V8.2 users get the heads up (display) 16th November 2018

- CGTech to showcase aerospace applications at Farnborough Airshow 15th May 2018

- VERICUT composite applications software Version 8.1 released 4th April 2018

technology at Jacobs Vehicle Systems.JPG)

Write a comment

No comments