Cycle time reduced in new CAM software

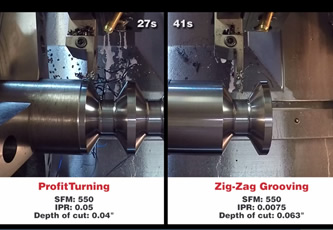

The latest version of the ESPRIT CAM software has been released. Named ProfitTurning the software is a lathe roughing strategy that significantly reduces machine cycle time, and has hurdled a series of tests, delivering a performance that promises to take machinists, engineers and industrialists to greater levels of precision, quality control and productivity.

ProfitTurning is fast, secure and efficient; it also extends tool life by significantly minimising wear. Compared to conventional ramping methods, ProfitTurning reduces machine cycle time as well as the frequency tooling inserts need to be replaced.

ESPRIT 2016 uses a physics-based cutting engine which provides the foundation for the technologies such as ProfitTurning.

While traditional cutting strategies consider only the geometry of materials, ESPRIT 2016 taps deeper into the science of how different industrial materials can be cut in the most efficient ways possible. Its new toolpath technology uses the principles of physics to formulate strategies for each cutting challenge.

To do that, ESPRIT 2016 inputs all relevant factors in the toolpath algorithm such as tool material, tool shape, workpiece material, tool speed, feed rate, chip deforming, chip load, machine tool power, acceleration and deceleration. This helps establish complete control of the cutting environment, allowing for optimal cutting everywhere along the toolpath.

Similar articles

More from ESPRIT

- Solutions delivered for Industry 4.0 smart manufacturing 15th September 2017

- Latest version of ESPRIT delivers smarter and faster machining 23rd May 2017

- Cycle time significantly reduced 21st December 2016

- Cycle time reduced in new CAM software 28th November 2016

technology at Jacobs Vehicle Systems.JPG)

Write a comment

No comments