igus UK Limited

Address:

51 Caswell Road

Brackmills Industrial Estate

Northampton

NN4 7PW

United Kingdom

Brackmills Industrial Estate

Northampton

NN4 7PW

United Kingdom

igus UK Limited articles

Displaying 321 - 338 of 338

Producing, testing and researching in Cologne

With the overall increase in turnover of 16.5 percent, igus®, manufacturer of tribo-plastic components and systems, has closed its books on the business year 2007. The consolidated group turnover has increased to 276 million euros from across its 26 branches around the world. igus® manufactures, tests and researches within a vast area of 20,000 m² at its headquarters in Cologne. In November 2007 construction work began on increasing factory space, as Managing Director Frank Blase reported at the Hanover Fair.

17th June 2008

New control cable family for the machine tool industry

Energy Chain and accessory expert igus® presented a new family of control cables at the Hanover Fair for use in energy chains across the machine tool industry. The oil-resistant Chainflex® cables CF77 and CF78 have been developed for dynamic applications with high cycle rates under high loads.

17th June 2008

Energy chain E6 low noise and vibration RWTH Aachen tests vibration behaviour of energy chains

Energy chains are used in production equipment, robots and tooling machines to guide and protect cables and hoses. Sometimes vibration can occur on the support channel and at the towing arm during the movement. The laboratory for tooling machines (WZL) and business operations RWTH Aachen carried out a study: vibration investigations on energy chains. The results were that the E6 energy chain from igus® stood out due to minimum vibration and maximum smooth running.

29th May 2008

Eco benefits of plastic plain bearings

A study has found that no less than half of all machine lubricants currently used seeps into soil and waters or evaporates into the atmosphere. According to a research team of chemists, mechanical engineers and environmentalists from the RWTH in Aachen, the estimates for Germany alone consume 250,000 tonnes per year, This corresponds to the amount required to fill 8,000 tankers.

29th May 2008

Texas: Robust Energy Chain System for oversized outdoor screen

Located at the Victory Plaza in Dallas, Texas, just outside the American Airlines Centre, You’ll find an oversized moving-screen LCD display, visible to everyone passing by. The Belgian Barco Group, a leading designer and developer of solutions for large-screen visualization have developed the display with eight 26ft screens. Robust igus® “E4/4” Energy Chains of the series 4040 with “Chainflex” fibre-optic cables, motor and control cables guarantees safe energy and data supply.

16th April 2008

iglidur® bearings come in many colours, but always green

Current estimations are that over 40% of all lubricants are ultimately released into the environment, by seeping into water or soil, or evaporating into the atmosphere. A study by a research team of chemists, mechanical engineers and environmentalists at the RWTH University in Aachen, Germany, found that this country alone consumes 250,000 tonnes of lubrication each year. To put this into perspective, this would fill 8000 standard tanker Lorries. Most countries have a threshold level permissible in waste streams, and hundreds of millions of pounds are spent annually treating the waste water to get to acceptable levels.

16th April 2008

Polymer bearings enhance labeller performance

High reliability, an easy set-up and modular components were of key importance for the Codeology team when designing its P100 Printer Applicator. The aim was that the print and apply labeller would be the best value for money and most reliable of its kind on the market. One key part of this was using polymer plain bearings in place of standard roller bearings.

7th December 2007

High performance polymers now machinable

igus now offers its iglidur materials as a stock bar, which means users can benefit from using high quality self-lubricating polymers in any machined component. It also means customers can now order a mechanically machined special size bearing of any dimension from igus in low quantities.

1st November 2007

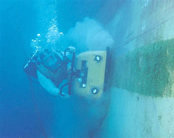

Hull cleaning machine uses polymer bearings

UMC International designed polymer plain bearings into a new boat hull cleaning machine for use by underwater divers. The bearings require no lubrication and are impervious to corrosion and salt water.

The Hampshire based company manufacture hydraulically powered hull cleaning machines, which typically have two rotating brushes. The vehicles can be powered forward or reversed, steered and the brushes raised and lowered on a gimbal mechanism. The usual cleaning speed is 1,000 square metres per hour.

27th September 2007

Extreme sports kite powered land board

These boards usually use heavy sets of ball race bearings in small diameter wheels as standard and must withstand bursts of speeds up to 30 mph. They are often used in dirty, salty and wet environments and so require regular cleaning and lubrication.

27th September 2007

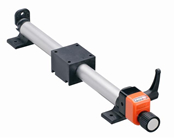

Slim, compact, maintenance-free

igus® has now developed a new maintenance-free linear unit, “DryLin® EasyTube, for format adjustments. This completely lubrication-free, extremely compact and lightweight system consists of just six individual parts: the leadscrew, tube, two clamping rings, an attachment flange and slide block. The system is available ex-stock with a diameter of 12, 25 or 30 mm.

12th September 2007

igus launches wireless system and more

igus reinforced its global position as a leading manufacturer of Energy Chain Systems when it launched numerous new product innovations and extensions at the Hanover show in April. The company revealed it had kept pace with rapid developments in the area of cable-bound chain systems, but also with inductive and wireless data transmission solutions. The key advantages typified by the new product developments included: compact size, easy assembly, higher speeds, lower noise and increased wear resistance.

12th September 2007

igus starts the ball rolling with high temp bearings

igus® now offers lubrication-free polymer ball bearings. According to the company, more and more customers were asking for maintenance-free solutions using roller bearings. Therefore, igus decided to fill the gap where standard materials were not effective by putting to good use its 20 years experience in tribologically optimised polymers and in-house test laboratory.

12th September 2007