EU Automation

Address:

Parker Court,

Staffordshire Technology Park,

Stafford,

United Kingdom

ST18 0WP

United Kingdom

Staffordshire Technology Park,

Stafford,

United Kingdom

ST18 0WP

United Kingdom

Phone: +44 (0) 1785 785 103

EU Automation articles

Displaying 21 - 40 of 52

Could remote working become the new normal?

Back in 2015, a survey of business owners by Virgin Media Business predicted that 60% of office-based employees would regularly work from home by 2022. This year, global disruption saw us prematurely exceed this figure. The majority of office workers began working from home to ensure business continuity. Could our current experiences of remote working mean that we continue to exceed this prediction? Here Alex Darby, Head of People at EU Automation, explores how businesses can embrace a new era of working.

11th September 2020

Three tips to improve data collection in manufacturing

Collecting data from devices connected to the Industrial Internet of Things (IIoT) is critical in smart manufacturing. It can help, among other things, monitor the health state of machines, track stock levels and gain precious insight on how to maximise productivity. However, this can only be achieved with comprehensive and accurate data. Here Neil Bellinger, Head of EMEA at EU Automation, explains how to improve data collection.

10th September 2020

Will competing Fieldbus ever evolve into open-source architecture?

As it evolved into the multifaceted enterprise it is today, Uber realised that to help its designers stay in sync, it had to provide common, open-source design libraries for all its services. The approach proved successful. So, what can automation professionals learn from it? Here Neil Ballinger, Head of EMEA at EU Automation, considers the case of Fieldbus and whether or not it will ever develop into an open-source architecture.

3rd September 2020

The problem of skills obsolescence in manufacturing

Could you recommend a good farrier? Chances are that, unless you own a horse, none will come to your mind. This is not surprising - after cars replaced horses, advanced knowledge of equine hoof care became a rare skill. The same is happening to a variety of manufacturing skills, fallen into oblivion after new technologies replaced older ones. Here, Neil Ballinger, Head of EMEA at EU Automation, talks about skills obsolescence and explains why it’s becoming a concern in manufacturing.

27th August 2020

COVID-19: Three changes for the engineering industry

Having shown overwhelming resilience in the face of adversity, the manufacturing and engineering industry is one that will be irrevocably changed as a result of the COVID-19 crisis. Here Neil Ballinger, Head of EMEA at EU Automation, looks at three aspects of engineering that will change for the better.

19th August 2020

How can deep learning benefit manufacturing?

In Christopher Nolan’s 2010 masterpiece Inception, the protagonist is a corporate spy who steals information by infiltrating people’s dreams, exploring the different layers of his victims’ subconscious to find a path to the desired information. Deep learning, a specialised form of machine learning, works in a similar way, recreating the complex architectures of our brain’s neural networks to find information hidden in big data.

6th August 2020

Is your global supply chain counterfeit-free?

In the age of e-commerce and global supply chains, the world markets provide opportunities for companies to grow and expand their customer base. However, complex supply chains also create more opportunities to introduce counterfeited products. Here Neil Ballinger, Head of EMEA Sales at EU Automation, explains why the problem is growing and how to tackle it.

30th July 2020

Three innovative approaches to obsolescence management

Evidence shows that components obsolescence is increasing rapidly. According to recent research by IHS Technology, in the year 2000 alone, component manufacturers issued 1,164 End-Of-Life (EOL) or product discontinuance notices, and the figure spiked to 5,506 by 2014. Though IHS forecasts that the number of such notices is going to decline, it’s always best to be prepared. Here Neil Balligner, Head of EMEA at EU Automation, looks at three innovative ways to proactively manage obsolescence.

15th July 2020

Is voice recognition technology ready for manufacturing?

Years ago, self-service kiosks were pure imagination. Today, grabbing products and paying without human interaction is an everyday activity. Now, companies like McDonald’s are going further and investing in voice-based technologies to speed up the customer’s experience even more. Here Neil Ballinger, Head of EMEA at EU Automation, explains what manufacturers can learn from large retailer kiosks, especially from the voice recognition systems.

29th June 2020

The different types of robots used to automate manufacturing

There is rarely, if ever, a one-size-fits-all approach to manufacturing. It is important that site managers know what considerations to make when choosing an industrial robot to automate their processes. In this article, Jonathan Wilkins, Director of EU Automation, discusses what manufacturers should consider when choosing what type of robot to invest in.

17th April 2020

How Industry 4.0 has changed the workforce

Loud speaker and subwoofer manufacturer, Paradigm Electronics has implemented robots to assist with product polishing. Humans collaborate with the robots but no longer perform the entire time consuming and laborious task themselves. In fact, most jobs have been altered in some way by the introduction of Industry 4.0. Jonathan Wilkins, Marketing Director of EU Automation, explains how job roles are changing with Industry 4.0.

23rd January 2018

Bring your phone to work – how smart technology is impacting industry

When Google Glass was first released to the public, it did not receive the expected response and the technology was deemed a failure. However, the technology did not disappear altogether, as the new and improved Google Glass is changing the factory floor. Here Jonathan Wilkins, Marketing Director, EU Automation, explains how everyday smart technology can impact industry.

29th September 2017

Technologies that are tipping the balance of Industry 4.0

Jonathan Wilkins, Marketing Director of obsolete industrial parts supplier, EU Automation explores the top three tipping points in the realisation of Industry 4.0. Industry 4.0 is still a burgeoning concept. However, rapid socio-economic developments and changes are causing disruptions to business and society and the fourth industrial revolution is beginning to take its first few steps towards the steep drop. There are three major tipping points that could push Industry 4.0 in the direction of becoming a fully realised concept.

6th September 2017

Designing for Industry 4.0

Back in 2009 when the Walkie Talkie skyscraper was constructed it was supposed to be an up-market living space for hundreds of London’s most wealthy citizens. However, it turned out the be the perfect example of designer myopia — a phenomenon where a product pleases the designer but doesn’t fit the brief.

27th June 2017

Protocol allows both new and legacy PLCs to communicate

Emulsifying agents such as egg yolk, Irish moss and soaps are soluble in both fat and water, and enable these two substances to combine which ordinarily isn’t possible. Similarly, the combination of data from multiple platforms is now possible because of the OPC UA protocol - an in-demand feature - as the Internet of Things (IoT) gains traction. Here, Jonathan Wilkins, Marketing Director of industrial obsolete parts supplier, EU Automation, discusses how the open source protocol OPC UA is beneficial for automation.

5th June 2017

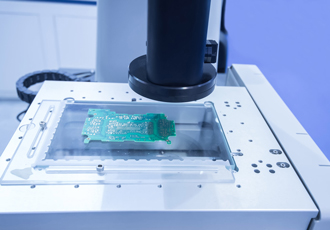

Machine vision is a crucial technology for Industry 4.0

There was a rapid burst of evolution around 540 million years ago, known as the Cambrian Explosion.One hypothesis for this is that the evolution of vision started an arms race. Complex vision improved the ability of animals to navigate and identify objects; it is now regarded as the most important sense.In industry, machine vision is being incorporated to develop industrial processes further, identify areas of improvement and enable intelligent locomotion within robotics.

30th May 2017

In the hands of industrial automation

Albert Einstein once said: “I fear the day that technology will surpass our human interaction. The world will have a generation of idiots.” This was before we knew the extent to which technology could change our lives. However, despite Einstein's worries, technology has improved quality of life for most people and has created new and more skilled jobs for those working in the engineering trade.

23rd May 2017

The demand driven by planning

Back in the 1950s there was a lot more than just sock hops and rock ‘n’ roll- in fact several popular technologies were designed and invented in the decade, including credit cards, automatic doors and the microwave. An important manufacturing concept, Materials Requirements Planning (MRP), was also born in this decade. MRP is a system to manage manufacturing processes through production planning, scheduling and inventory control.

31st March 2017

resized.jpg)