Burkert Fluid Control Systems

Address:

Fluid Control Centre

1 Bridge End

Cirencester

Gloucestershire

GL7 1QY

United Kingdom

1 Bridge End

Cirencester

Gloucestershire

GL7 1QY

United Kingdom

Burkert Fluid Control Systems articles

Displaying 41 - 60 of 139

Improved control of burners & boilers delivers efficiency savings

The use of boilers and their associated burners is widespread across a large number of industries and they form a crucial part of many processes, especially for the generation of saturated steam. However, with ever-increasing fuel costs and the heightened focus on CO2 emissions, it is becoming more important than ever to ensure that the efficiency of this equipment is maximised. One key factor is employing accurate and reliable sensor technology which can be seamlessly connected into the main control system.

12th November 2015

Controlling CIP / SIP in food processing applications

Implementing an effective cleaning process that will deliver the required hygienic standards requires expertise in valve design and process control techniques. It is important that both design and process engineers understand the importance of the right design, both in terms of the pipework and the control valves.

24th September 2015

Energy saving with process valves

Many industries use steam and compressed air as sources of heat and motive power and need to be managed properly in order to be used efficiently. Both are expensive to generate and so improving the level of consumption can have a significant impact on production costs. By assessing an existing process control structure and looking at alternatives, it is almost always possible to identify areas for improvement and start a program of worthwhile energy saving initiatives.

21st September 2015

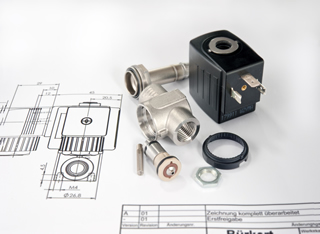

Solenoid valves – one for every occasion

Solenoid valves perform an essential task in the control of fluids and gases and the basic design has been refined over the years to allow them to be utilised in a wider range of applications. Modern fluid control systems present a number of challenges that require the correct design of solenoid to achieve a reliable and efficient control process. Kelly Booth, solenoid valve specialist at Bürkert UK, looks at the different valve types and their suitability to various applications.

20th August 2015

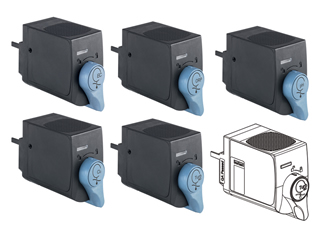

Control of water treatment in cooling towers with Bürkert multiCELL

The use of cooling towers is widespread across many industries and the water treatment process within these systems performs a crucial role which needs to be carefully controlled. The latest Type 8619 multiCELL transmitter/controller from Bürkert delivers a modular solution which is compatible with the company's complete range of sensors, control valves and dosing pumps.

28th July 2015

Solenoid valves - some are more equal than others

Process control throughout a vast array of industries relies heavily on the humble solenoid valve and its ability to perform both reliably and efficiently. Michael Hannig, Global Product Manager for Solenoid Valves at Bürkert Fluid Control Systems, looks at the improvements in design that have allowed an increasing number of processes to rely on this essential device.

28th July 2015

Design & maintenance crucial to avoiding water hammer in steam systems

Steam is a very versatile and efficient carrier of energy and it is used in a wide range of industrial processes. It is intrinsically safe and frequently used in food and pharmaceutical production; however, it must be treated with respect. The apparatus used to convey and control steam must be properly designed and maintained to avoid energy losses as well as damage to boilers and other plant by water hammer, which can be particularly destructive when left unchecked.

13th July 2015

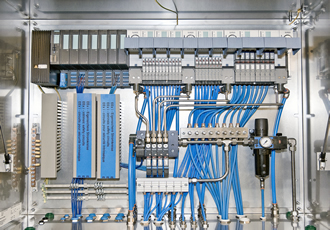

Bürkert hazardous area rated pneumatics automate world’s fastest whisky bottling plant

The combination of Bürkert’s AirLINE Ex 8650 valve islands and Siemens intrinsically safe SIMATIC ET 200iSP distributed I/O system is providing an ideal, safe, compact and modular pneumatic control solution for a global drinks company in Scotland. The equipment has been used in replacement Ex rated control panels at the company’s bottling plant in Glasgow: the Fastest whisky bottling plant in the world.

4th June 2015

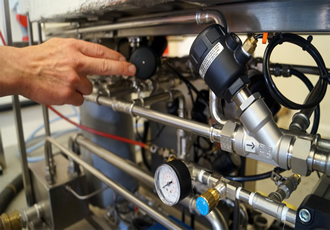

Super Efficient New Autoclave Uses Compact Bürkert Process Valves To Meet Cost And Performance Targets

The latest Logiclave type vertical closing autoclave from ESTS claims to reduce running and maintenance costs by up to £60,000 over an average 10 year operating period. The secret to achieving this figure is low maintenance, high reliability and low energy consumption. This is largely made possible by the use of an innovative flash steam generator and a combination of Bürkert Type 2000 angle seat steam valves and rotary ball valves.

7th April 2015

Intelligent control for food processors

The general trends in the automation of food processing have been heading towards more precise control and more information being gathered at device level. It is important for process engineers to appreciate which control structure would be most appropriate for their particular application.

8th January 2015

Fluid control, design and manufacturing expertise from Bürkert now available direct to OEMs

Designing modern flow control components for life science, analytical and medical applications can be a difficult task in itself, but designing them from a manufacturer’s perspective incorporates additional complexity. Bürkert Fluid Control Systems is making its entire design and manufacturing expertise available to OEMs to help them produce more cost effective and reliable products.

2nd December 2014

New multiCELL from Bürkert provides localised sensor signal management

The latest multiCELL Type 8619 from Bürkert offers process control engineers a modular, multi-channel local controller that is capable of operating with a wide range of sensors and process I/O. The 2014 range includes both the original panel mount version and the latest external version that offers ingress protection up to IP67 as well as accepting AC power supplies.

14th October 2014

New water control and analysis system from Bürkert offers multi-functions and simplicity with novel plug-in Sensor Cubes

Bürkert Fluid Control Systems has developed a new solution for performing five high-priority monitoring and analysis tasks for water processing. Using smart Sensor Cubes, the new Online Analysis System Type 8905 can be used to monitor and control pH, Chlorine, conductivity, ORP and turbidity from one compact unit. Settings and status can be accessed via a 7” touch screen display, while USB, Ethernet and fieldbus connectivity offer easy integration and flexible communications options.

3rd October 2014

Flow meters use calorimetric principle for assured accuracy

The Type 8007 and Type 8008 flow meters, designed to measure especially large flow rates, have been introduced by Bürkert. By using the calorimetric principle of flow measurement, the accuracy of these new flowmeters can be assured since it is unaffected by changes in temperature and pressure.

26th August 2014

Correct valve sizing is vital for steam applications

Steam is used in a wide range of industries for a variety of processes, from a basic small heating circuit to large scale hygienic steam production. Ian Webster, Hygienic Processing Segment Manager at Bürkert UK, looks at some of the basic calculations that should be understood by design and maintenance engineers in order to achieve a safe and efficient process.

19th August 2014

Understanding sensors within a fluid control system

Very little can be achieved without raw data supplied by sensors in today's fluid control systems. These sensors can help facilitate a variety of tasks from displaying process information and performing control functions to operating alarms, but each one has to communicate information to a process controller. Bürkert's Kieran Bennett looks at the range of sensors available, the different technologies used in their design and how the application affects the specification.

19th August 2014

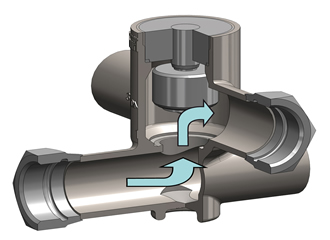

Modular valve design improves system flow characteristics

A modular valve body design, incorporated into Bürkert’s INOX valve range, has increased the flow coefficient of a conventional angle seat valve, reduced energy requirements and improved system flow characteristics. Due to the seperate inlet level and outlet level, the fluid flow now only has to be redirected once through 180˚ which increases the flow coefficient.

13th August 2014

Bürkert Unveils New Intelligent Valve Positioner

Intelligent valve positioners, through their compact and hygienic design are the ideal component as part of a decentralised automation process in a hygienic environment. The ability to control pneumatic actuation, feedback and diagnostic functions with the additional benefit of fieldbus communication, in combination with a suitable control valve, makes this arrangement very useful in a range of process automation tasks.

2nd July 2013

Valves – when to repair or replace?

When it comes to process, pilot and actuation valves, the question of whether it is advisable to repair or replace a worn or intermittent unit is worth considering, regardless of the type or the size. Tom Carnell, Systems Applications Manager, from valve manufacturer Bürkert UK gives his advice as a basic guide.

25th June 2013

Bürkert Launches New Range of Intelligent Valve Control Heads

Thanks in part to the popularity of Bürkert’s original 8681 control head that was designed specifically to bring control and connectivity to 3rd party hygienic process valves, Bürkert has now launched three new models in the range. The 8691, 8685 and 8695 all offer the same connectivity and functionality as the original, but now fit (with model specific adapter kits) a much wider range of valves, including some popular ranges from Bürkert‘s own catalogue.

17th June 2013