Gravure printing line saves energy after varnishing station upgrade

A German-based family run furniture and interior design business, manufacturing finish foils and decor paper, has integrated three GEW-made 240cm wide NUVA2 UV lampheads with a RHINO power supply, in order to upgrade the final varnishing station on one of its gravure printing lines with a new UV curing system.

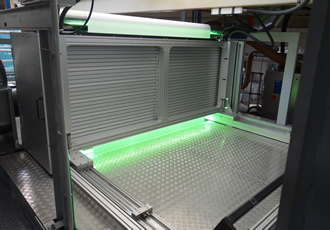

The three UV lampheads are positioned vertically, one after the other, so as to achieve the maximum UV curing effect. The UV system is mounted in a custom designed aluminium frame that integrates a retractable cooling panel and water cooled quartz window to prevent the heat transfer onto the substrate.

The installation is based on a Cerutti machine with five print stations using water-based inks with IR drying. The configuration is now able to print and varnish substrates up to 2,250mm wide with speeds up to 120m/min and mainly produces finish foils intended for wrapping and laminating on wood-based materials.

Managing Director Christian Bungard explained: “On our previous system we certainly had issues with excessive heat radiation and the extremely short life cycles of the UV lamps. Our clients demand a quality product and expect us to be an absolutely dependable supplier. For this reason it was one of our main objectives to convert to a low maintenance operation with the highest reliability.”

The decision in favour of the GEW UV system was due to the requirement that major investments go only into reliable high performance technologies. “GEW was able to offer us a comprehensive package of efficiency and reliability with UV lamp life cycles of several thousand hours.” Bungard added. For complete peace of mind the GEW package comes with the security of a five year warranty.

Embedded Service, which is part of GEW’s package, enables engineers to remotely access performance data and proactively detect parameters outside the permitted tolerances and immediately take the necessary maintenance steps even before a fault can develop. This type of preventive remote maintenance ensures that the entire UV system works at its peak performance at all times, thus avoiding unplanned machine stoppages and a waste of resources.

The new UV system based on GEW’s highly efficient NUVA2 lampheads boasts particularly fast switch-on and cool-down cycles achieving considerable electricity and time savings. Bungard concluded: “The NUVA2 UV lampheads together with the RHINO power supply reduce our electricity consumption by some 50% allowing us at the same time to further increase our capacity and enjoy faster, more stable production.” Since the initial installation Likora has already invested in another two systems to harmonise its UV technology across the site.

Similar articles

More from GEW

- Etygraf installs flexo label printing system 22nd February 2017

- Investment leads to enhancing KBA presses with GEW UV 30th January 2017

- Gravure printing line saves energy after varnishing station upgrade 28th October 2016

- Fully aircooled LED UV curing system 21st June 2016

.jpg)

Write a comment

No comments