Electrox Raptor Is A Winner For GPR Motorsport

24th October 2011

Source:

Electrox

For suspension specialists GPR Motorsport, speed and accuracy isn’t just important to the BTCC (British Touring Car Championship) teams they supply, but to its entire manufacturing process.

The Buckinghamshire-based company has invested in an Electrox Raptor EF Technology laser with D-Box Workstation to ensure that its marking system is fast and efficient and remains legible even in the most testing conditions.

Founded in 1999, the company is a tier-one supplier of suspension units to four BTCC teams, including Frank Wrathall’s Dynojet Toyota Avensis and Rob Austin, driver of a Rob Austin Racing Audi A4, who are currently lying 11th and 14th in the championship* respectively.

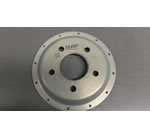

To keep costs down, BTCC specifies that parts, including the suspension units must be controlled, meaning the teams cannot replace or alter them in any way. It is therefore essential that the suspension units are clearly marked so they can be identified quickly and easily by race scrutineering; the checks before and after a race to confirm that parts are correct and vehicles are safe.

When specifying the laser, Gary Blackham, partner of GPR Motorsport explains the company wanted a solution that was extremely accurate, fast and efficient. And with the Electrox Raptor and D-Box Workstation that’s exactly what they got. The Raptor is an EF Technology laser and is specifically designed for the high speed marking of metal and plastic. It can permanently mark 1,000 characters per second with an accuracy of five microns.

Gary said: “Prior to getting the Electrox Raptor, all our marking was done by mechanical engraving. This was a slow and laborious process that required a considerable amount of stopping and starting.

“Not only is the Raptor considerably quicker at marking, once you’ve programmed in the batch numbers, you just reload the machine and start marking; it automatically starts at the correct batch and serial number, so you don’t have to set it manually. It saves a huge amount of time, which of course, adds to our bottom line.”

It is also important that the marks produced are of high quality and offer good legibility, not just at the time of marking, but in the most challenging of conditions, because in BTCC, legibility can be tested to the extreme.

“The BTCC Drivers are at the top of their game,” explained Gary. “They race to the limit and this means that from time to time they crash. Our suspension units are designed to last a season, so if it’s a small spill, the car is mended and the parts reused. But after a big crash, we’ll get the suspension unit back to see how it performed under intense stress. It’s essential that we can read the markings so we can trace back how each part was manufactured and analyse its performance throughout its lifetime.”

With laser marking, this is achieved using an intense beam of light, which permanently changes the colour of the surface of the material, in this case metal. The D-Box Workstation is Windows compatible and can be programmed via a computer, thus offering exceptional control, flexibility and accuracy. As a result, the laser can be used to mark barcodes, two dimensional codes such as Data Matrix, date coding and automatic serialisation as used by GPR Motorsport.

Like all of Electrox’s products, the Raptor and D-Box are designed with the user in mind and are extremely easy to use with the minimum of training. The workstation is manufactured from welded steel and features a lift-up door, laser safe viewing window and fume extraction port ensuring the whole marking process is safe. What’s more, there are no inks, acids, or solvents to handle and store, and because there’s no tooling to wear out or consumables to replace, operating costs are low.

GPR Motorsport has reported that the laser marking system had proved so effective that the company is not just using it for the BTCC suspension units but on parts manufactured for retail too. Gary said: “Part marking is essential in the automotive industry as it ensures accurate product control. I’d definitely recommend the Electrox Raptor to anyone looking for a fast, efficient and cost effective solution.”

To keep costs down, BTCC specifies that parts, including the suspension units must be controlled, meaning the teams cannot replace or alter them in any way. It is therefore essential that the suspension units are clearly marked so they can be identified quickly and easily by race scrutineering; the checks before and after a race to confirm that parts are correct and vehicles are safe.

When specifying the laser, Gary Blackham, partner of GPR Motorsport explains the company wanted a solution that was extremely accurate, fast and efficient. And with the Electrox Raptor and D-Box Workstation that’s exactly what they got. The Raptor is an EF Technology laser and is specifically designed for the high speed marking of metal and plastic. It can permanently mark 1,000 characters per second with an accuracy of five microns.

Gary said: “Prior to getting the Electrox Raptor, all our marking was done by mechanical engraving. This was a slow and laborious process that required a considerable amount of stopping and starting.

“Not only is the Raptor considerably quicker at marking, once you’ve programmed in the batch numbers, you just reload the machine and start marking; it automatically starts at the correct batch and serial number, so you don’t have to set it manually. It saves a huge amount of time, which of course, adds to our bottom line.”

It is also important that the marks produced are of high quality and offer good legibility, not just at the time of marking, but in the most challenging of conditions, because in BTCC, legibility can be tested to the extreme.

“The BTCC Drivers are at the top of their game,” explained Gary. “They race to the limit and this means that from time to time they crash. Our suspension units are designed to last a season, so if it’s a small spill, the car is mended and the parts reused. But after a big crash, we’ll get the suspension unit back to see how it performed under intense stress. It’s essential that we can read the markings so we can trace back how each part was manufactured and analyse its performance throughout its lifetime.”

With laser marking, this is achieved using an intense beam of light, which permanently changes the colour of the surface of the material, in this case metal. The D-Box Workstation is Windows compatible and can be programmed via a computer, thus offering exceptional control, flexibility and accuracy. As a result, the laser can be used to mark barcodes, two dimensional codes such as Data Matrix, date coding and automatic serialisation as used by GPR Motorsport.

Like all of Electrox’s products, the Raptor and D-Box are designed with the user in mind and are extremely easy to use with the minimum of training. The workstation is manufactured from welded steel and features a lift-up door, laser safe viewing window and fume extraction port ensuring the whole marking process is safe. What’s more, there are no inks, acids, or solvents to handle and store, and because there’s no tooling to wear out or consumables to replace, operating costs are low.

GPR Motorsport has reported that the laser marking system had proved so effective that the company is not just using it for the BTCC suspension units but on parts manufactured for retail too. Gary said: “Part marking is essential in the automotive industry as it ensures accurate product control. I’d definitely recommend the Electrox Raptor to anyone looking for a fast, efficient and cost effective solution.”

Similar articles

More from Electrox

- Electrox lasers score a hole in one for Midas Golf 14th February 2013

- Electrox Opens US Applications and Demonstration Center and Makes Senior Appointment 14th November 2011

- Electrox Raptor Is A Winner For GPR Motorsport 24th October 2011

- The Minelli Corporation Appointed as Swiss Distributor of Electrox 29th November 2010

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex

.jpg)

Write a comment

No comments