Southco re-brand takes a customer centred approach

With a recent re-brand under its belt, Electronic Specifier recently attended the Southco European Headquarters, in Worcester for the company’s ‘Get to know me’ event where it officially launched its new brand initiative. The day began with a speech from Richard Pearman, General Manager in Europe who explained Southco, now a global company with 100,000 customers and products started off locally. With manufacturing plants all over the world, the company typically creates 350 products every year and offers modifications and services to customers.

The company is spilt between automotive and diversified technologies, as Pearman explained: “Balance is key, it is all about creating a strong foundation between all areas of the company.” Southco made it clear that it plans to move with digitalisation, as its products can help the IoT movement within both markets.

Southco works with a lot of customers, and a lot of bigger names, for example the company a few years ago helped with the development of the Mercedes S class headrest, as the curved features used the Southco hinges within. Pearman explained: “We provide premium technology to premium customers, which will then see other customers follow on.”

Pearman added that the company works primarily with a ‘customer first’ culture in mind: “This is so we provide the best total solution, best total cost and best product.”

Ulrike Sturman, Industry Marketing and Communications Manager explained that Southco’s key message from this re-brand launch is to show how the company positions itself. “It’s a new message rather than a new look, and that message is that we are customer first and focused.” From this re-brand Southco is now in the process of reconnecting and rebuilding within distributors and customers.

With a slight change to the logo, getting rid of the tag line underneath the company no long has one appearing underneath but still conveys the message: “Creating first impressions that last.”

Sturman explained that a first impression can help when it’s something brand new, but a lasting impression can also be made when something is already ten years old. “We want the impression to last, so we do a lot if in-house testing and pride ourselves on reliability and durability.”

Stewart Beck, Global Product Manager explained the company is diverse and dynamic which is great as you get to see the whole picture. “A hinge can change your emotional response to a product, we proved this in our work we did with Volvo.”

Beck added that a hinge can also sometimes do something you may not expect it to – it can lift an incredible weight in some situations: “It’s not ‘just’ a hinge.”

Furthering this Kim Clive, Product Specialist presented to the audience all about rotary systems, quarter turn fasteners and compression latches and taught us that some of these products can be in the simplest applications that we use every day such as a car door.

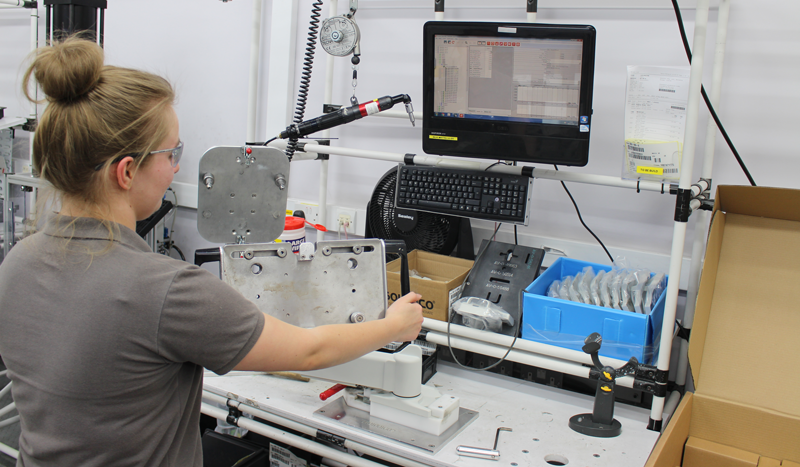

Finally before a factory floor tour, where the magic happens Neil Swann, Field Application Engineer, educated us about the work Southco does with Electronic Access Solutions (EAS).

These Southco solutions again can be found almost everywhere in our everyday lives from smart mobility such as e-bikes and scooters to reduce traffic, to smart healthcare in controlled access units for medication to eliminate human error and for safety. From data centers to smart retail and smart energy plants.

Swan explained the next big solution that Southco are working on is Bluetooth Wireless Control. He said: “There is a big future for Bluetooth controls and latches in Electronic Access Solutions, all thanks to the smartphone we all have access to it, and it’s everywhere.”

Whilst visiting the factory floor to see all the workers in the working environment a Southco worker told the crowd of the old ‘Southco myth’: “You are never more than ten metres from a Southco product.” Something I will constantly be looking out for from now on.

Pearman concluded: “What do we see in the future? Growth. We have a new Polish manufacturing facility in Rzeszow, which is soon to be finished with our customers in mind as we have a large customer base in Germany and we like to be local for our customers.”

Similar articles

More from Southco Europe Ltd

- Scoring a Win for Accessibility 29th November 2019

- Compact electronic slide bolt offers door and latch status monitoring 16th July 2019

- Brighter latching solutions for lighting innovation 12th April 2019

- Southco re-brand takes a customer centred approach 21st September 2018

Write a comment

No comments