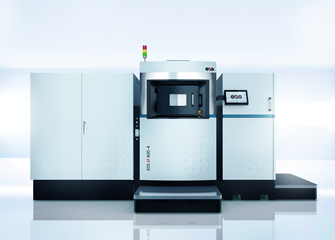

DMLS system designed to shatter boundaries of manufacturing

System for Direct Metal Laser Sintering (DMLS) will be introduced at the IMTS show in Chicago, 12th to 17th September, by the leading company for high-end Additive Manufacturing (AM) solutions, EOS. Designed for industrial applications, the ultra-fast, quad-laser system expands the EOS DMLS offering by building on established EOS technology, yet taking it to the next level in terms of productivity, part quality and scalability to meet manufacturing requirements.

Andreas Graichen, Group Manager, Finspang Additive Manufacturing Centre of Competence, Siemens Power Generation Services stated: “We chose the EOS M400-4 system to bring our AM activities to the next level: from a small scale, single laser unit to a larger scale, multiple laser unit. By using a wider building platform, with the higher productivity it provides, and pairing it with a new handling system, new thinking in gas turbine design can be brought into the industrial workshop.”

Graichen added: “The Additive Manufacturing technology provides us with the speed and efficiencies needed to progress in the energy industry’s fast-moving digital environment. And as such makes Siemens a unique player in the field of highly efficient power generation technologies.”

“As the system offers a modular platform designed for industrial 3D printing, it can easily be integrated into existing production environments and the customer set of future innovations,” he commented.

Building on the trusted EOS metal AM benchmark

The EOS M 400-4 expands the high-performance offerings of DMLS systems. It offers a large building volume of 400x400x400mm and is equipped with four 400W lasers operating independently in 250x250mm squares each including an overlap of 50mm. The exceptional beam and power stability ensures highest DMLS part quality. The system builds on the well-established and validated process of the EOS M 290 technology. It takes innovation to the next production level as it quadruples productivity. As such it is the perfect choice for those Additive Manufacturing applications that need an up to 4x faster production of metal parts.

New EOS ClearFlow process gas management system

As part of the EOS M 400-4 system, the patented EOS ClearFlow process gas management technology ensures optimal and consistent processing conditions. It distributes the process gas in an intelligent way to avoid interference of the lasers with side products of the melting process. In addition, the integrated industrial-grade, recirculating filter system with its long filter lifetime significantly reduces operating times and expenses.

Intuitive software, improved usability, EOSTATE Monitoring Suite

Usability and workflow on the EOS M 400-4 have been designed to meet demanding production requirements. The intuitive software offers workflow flexibility and efficiency. The system is easily operated via a touch screen and a task-based graphical user-interface. The extensive EOSTATE Monitoring Suite ensures compliance with the requirements of industrial production: it enables monitoring of the powder bed, of a variety of parameters as well as the laser power. Data Preparation and calculation is separated from the building process: the file prepared at desk is transmitted via the network. The system focuses entirely on building parts.

Material and process portfolio

Initially, the materials EOS Nickel Alloy HX as well as EOS MaragingSteel MS1 will be available for the EOS M 400-4 and more materials and processes will follow soon. Parameters can be modified to meet individual application requirements using the EOS ParameterEditor.

Similar articles

More from EOS Innovation

- High-performance materials broaden range of aerospace applications 22nd February 2018

- Shaping the future of manufacturing with EOS 13th November 2017

- Camera-based monitoring of build process significantly cuts costs 19th June 2017

- Industrial 3D printing technology for factories of the future 24th April 2017

Write a comment

No comments