Camera-based monitoring of build process significantly cuts costs

Expanding its EOSTATE monitoring suite, EOS have designed an additional tool. EOSTATE Exposure OT, the first commercial system for optical tomography worldwide, now provides real-time, camera-based monitoring of the additive, metal-based build process, based on the EOS M 290 system. The solution fully maps each part throughout the build process, layer by layer, regardless of its geometry and size.

Partnership with MTU, pilot customers Liebherr and IPC

The solution was developed in close collaboration with EOS strategic partner MTU Aero Engines. EOSTATE Exposure OT enables the partner to significantly reduce costs for downstream, non-destructive examination in technical computer tomography (CT), as potentially defective parts can be rejected at an earlier stage. At MTU Aero Engines, EOSTATE Exposure OT was primarily developed for series manufacturing purposes, where it has been in use for several months and meanwhile proven its efficiency. The two other pilot customers, Liebherr and IPC, will also continue to use the system after the pilot phase and integrate it in their manufacturing processes.

“At MTU Aero Engines we recognised the potential of Additive Manufacturing early on. However, until now we didn’t have the experience and the volume of data needed to sufficiently evaluate the quality of the parts and transfer the technology to large-scale manufacturing. We are confident that we will be able to do so with EOSTATE Exposure OT,” said Dr. Jürgen Kraus, Senior Consultant Additive Manufacturing at MTU.

He added: “The new OT solution has meanwhile proven itself in practical tests and we are very happy that other customers will now be able to benefit from it, too. It provides genuine added value.”

Alexander Altmann, Lead Engineer Additive Manufacturing/TRPI Research and Technology at Liebherr, said: “We are now using EOSTATE Exposure OT and EOSTATE MeltPool from EOS and expect both technologies to give us a profound understanding of the phenomena relevant for quality when additively producing titanium parts.”

He continued: “In the medium to long term, we will be looking to produce highly complex flight control system components using Additive Manufacturing. Here, real-time process monitoring as well is key to create an economically viable process chain. Widely used non-destructive examination processes such as CT are quite elaborate and expensive for manufacturing valve blocks.”

Optical tomography: How the process works

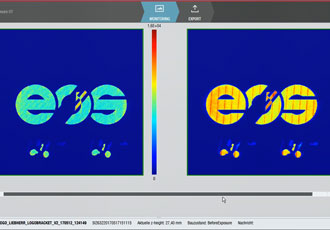

With optical tomography (OT), the system deploys a high-resolution camera to seamlessly monitor the exposure process. A highly dynamic industrial camera records the complete building platform at high frequency in the near-infrared range throughout the entire Additive Manufacturing process, thereby providing detailed data on the melting behavior of the material across the entire build space.

Based on the data captured, the melting behavior of steel, aluminum, titanium, and a variety of alloys involved in the additive build process can be analysed and monitored in great detail using special software. If certain results deviate from a ‘normal range’, which can be individually defined by means of parameters, these areas are marked. The growing volume of data makes it possible to determine the impact of these so-called indicators on the quality of the manufactured parts with ever greater precision.

EOSTATE Exposure OT is a self-learning system that becomes increasingly intelligent the more data it is fed. The more precisely users become familiar with the specific parameters of their components, the better they can assess the quality and density of the parts they are manufacturing. The ultimate aim is to recognise possible sources of defects during the building process and reject any defective parts.

Similar articles

More from EOS Innovation

- High-performance materials broaden range of aerospace applications 22nd February 2018

- Shaping the future of manufacturing with EOS 13th November 2017

- Camera-based monitoring of build process significantly cuts costs 19th June 2017

- Industrial 3D printing technology for factories of the future 24th April 2017

Write a comment

No comments