NI Week: Wireless devices end manual data collection.

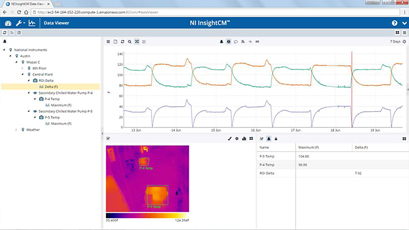

Wireless monitoring hardware has been announced for NI’s InsightCM, a solution for online condition monitoring with full access to data and customisation with the InsightCM Software Development Kit. The new wireless devices automate the otherwise manual process of route-based data collection.

It allows reliability engineers more time to analyse data and solve problems and less time climbing stairs with instrumentation and personal protection equipment to collect data.

Plant maintenance teams that rely on manual, route-based data collection for plant assets can now achieve daily visibility into machine health.

Unlike many wireless devices on the market, the NI wireless devices transmit diagnostic quality waveform data back to the InsightCM server so subject matter experts can immediately respond to alerts with a laptop rather than making a trip to the plant.

This wireless hardware helps plant owners connect a greater percentage of their assets to IT networks by drastically reducing the costs associated with installation: conduit, cabling and plant design work.

“It takes us days to install continuous monitoring systems, but with wireless, it’s closer to hours so we can connect more equipment in less time and for less cost. More connected assets will mean fewer routes and a shift in focus to data analysis rather than data collection,” said Chuck Requet, group leader, Engineering for Generation Services, Louisville Gas & Electric and Kentucky Utilities Energy. “For the same FMax [useable frequency range], the NI wireless device data quality is as good as our wired continuous monitoring devices.”

The wireless monitoring hardware encompasses two separate devices with support for InsightCM.

The NI Wireless Vibration Measurement Device connects 12 standard piezoelectric accelerometers, or ±30 V sensors such as proximity probes, and is ideal for hard-to-access equipment that already has sensors installed.

It connects to the sensor junction box that would otherwise be used for handheld route instrumentation. AC, DC and battery-powered options are available.

The battery-powered NI Wireless Vibration Sensor has an onboard MEMS triaxial accelerometer with temperature sensor.

Maintenance teams install the wireless sensor with the same installation methods used for piezoelectric accelerometers: magnetic-mount accessory or epoxy pads.

Similar articles

More from NI-Emerson

- NI Week: Wireless devices end manual data collection. 23rd May 2019

- Application software aids operational efficiency 9th May 2018

- Design software customises device tests 23rd January 2018

- Devices collect synchronised data in severe environments 13th December 2017

Write a comment

No comments