Cavitation detection system averts pump problems

A cavitation detection system has been unveiled by Yokogawa IA. It will be available from January 31. By detecting cavitation, quantifying information, and displaying the data in real time, this system provides an early indication of conditions that can result in a degradation in pump performance.

By detecting problems early, before damage occurs which can cause an increase in both vibration and noise levels, this solution improves the efficiency of plant maintenance.

Cavitation in fluids can cause damage to pumps. To minimise this damage, it is necessary to detect cavitation at an early stage and take corrective measures such as adjusting the flow rate. One issue, however, is that there has been no way to quantify cavitation.

In addition, since cavitation occurs inside equipment, it is impossible to visually check whether this is occurring.

Cavitation is usually detected by field personnel who rely on experience gained on the job to detect changes in vibration and noise levels that are caused by excessive cavitation.

However, even highly experienced plant personnel and specialists can miss these early signs, and such problems may go undetected until the inevitable increase in vibration and noise occurs.

In its analysis of this problem, Yokogawa has focused on the principle that there is a direct relationship between differential pressure and cavitation, and has created a condition monitoring solution that involves the quantification of cavitation based on pressure data.

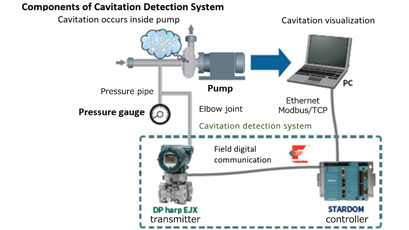

The system that Yokogawa has developed consists of a STARDOM FCN-500 network-based control system, a Yokogawa cavitation detection logic program, and a highly accurate (±0.075%) DPharp EJX110A differential pressure transmitter, and relies on the FOUNDATION Fieldbus industrial digital communication standard to link these components.

At 100ms intervals, the DPharp transmitter measures the pressure inside the target equipment, and this data is transmitted via the fieldbus network to the STARDOM FCN-500 system for processing in real time by the logic program.

This system is therefore able to detect cavitation issues early on, allowing field personnel to take quick remedial action by, for example, reducing the flow rate to a level that suppresses cavitation without interfering with production line operations.

Valves, pumps, and other types of plant equipment can all experience problems such as cavitation which are caused by anything from the opening/closing of a valve, a change in viscosity level or some other physical property of a liquid, or a change in the external environment.

Field personnel havetraditionally relied on their own experiences and the use of analytical tools to find out what is causing these problems. Thanks to the development of this new system, they will have a tool that will help them troubleshoot problems with greater efficiency by identifying and quantifying cavitation in plant equipment.

Target markets are oil, petrochemicals, chemicals, iron and steel, pulp and paper, water supply and wastewater treatment, pharmaceuticals, food, etc.

Applications include maintenance of plant facilities such as pumps that tend to deteriorate due to cavitation.

Similar articles

More from Yokogawa IA

- Cavitation detection system averts pump problems 17th January 2019

- Network function enhances digital indicator 25th April 2018

Write a comment

No comments