Micro dosing; creating an application specific solution

Industries that employ micro dosing technology such as pharmaceuticals, medical applications and inkjet printing represent a diverse variety of applications. What is essential is that the most appropriate design and materials choice can be made for each one.

Author: Tony Brennan, Field Segment Manager Gas & Micro for Bürkert Fluid Control Systems.

The two most common methods of micro dosing are time-pressure dosing and volumetric dosing, each has its strengths and most appropriate applications, so making the right choice is essential to a successful installation.

Control of time and pressure

Creating a micro time pressure dosing system requires a range of components that need to be carefully linked together to deliver a reliable and effective solution. The initial starting point is the pressure vessel where the dosing fluid is stored. This needs to be fitted with both level sensors and a highly accurate pressure transducer to ensure a constant supply of fluid at the correct rate.

The fluid is initially controlled by flow control valves which deliver it to the dosing system. In some cases, a conductivity probe can be fitted at this point to check that the correct fluid is being used. The dosing system itself will be based around a precision flow control valve that meets the specifications of the process.

Time pressure dosing needs two controlled circuits, one to control the dispensing of the fluid and the other to maintain the pressure of the propellant gas that is used to drive the liquid through the system. With a known system pressure, the volume being dispensed is controlled by the defined opening time of the valve. This operation is usually controlled by a PLC via a HMI.

This design has a number of benefits: It is capable of delivering a high dosing frequency as well as controlling the dosing speed. The dosing volume is variable, to the point that continuous dosing is also possible. This design is typically compact in dimensions and can be arranged to deliver several different fluids into one process.

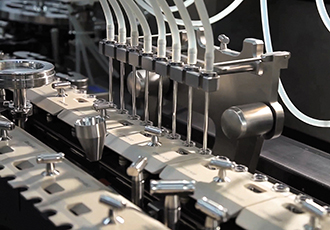

Modern valve design has enabled micro precision while at the same time maintaining the highest hygiene standards. Onboard circuit boards enable calibration and process parameters to be retained within the valve assembly while network connectivity is assured through fieldbus communications.

This type of system is more commonly seen in pharmaceutical, medical and biotech applications as well as drinks vending machines, where speed and hygiene are prerequisite.

Volumetric dosing

For applications that still require accuracy as well as a high dosing speed, micro dosing pumps provide the answer. These are excellent for continuous dosing applications and their more simplistic arrangement makes them very cost effective. They are often used in process filling, the dosing of adhesives or lubricants as well as environmental analysers.

Again, micro pumps are designed for a variety of applications. Often the dosing amount is controlled by a frequency generator and accuracy levels are typically ±2%. In some cases, all the wetted parts can be easily changed, and the fluidic chamber can be designed as a disposable item.

Selecting the most appropriate materials and specifications is best done with assistance from a manufacturer, which has the expertise and application knowledge to create the best solution.

Installed reliability and precision

The whole purpose of micro dosing systems is to deliver repetitive volumes of fluid quickly and accurately. Moreover, the accuracy must not decline over the lifetime of the dosing valve, so continued precision and long-term reliability are essential. To that end, Bürkert has developed a family of microfluidic valves that can operate at high pressures with a typical service life of 200 million cycles.

Within this range there are specialist products, such as the Type 6712 Whisper valve, which offers fast acting control and an internal volume of just 5µl. Products such as this can be combined with a host of compatible control equipment to create tailor-made systems for a wide variety of applications.

From the initial application assessment, through design and construction to installation and commissioning, working with a single supplier can reduce complexity and deliver the most efficient solution.

Of course, these systems need to fit seamlessly with the existing process equipment, especially in terms of communications. As an expert in fluid control systems, Bürkert offers a complete turnkey solution for all micro-dosing applications, including complete integration with the existing network topology.

Similar articles

More from Burkert Fluid Control Systems

- Continuous water quality analysis for boreholes 6th July 2020

- Controller delivers precision microlitre dosing 14th May 2020

- Multi-medium testing facility for fluidic components 19th March 2020

- Micro precision for time-pressure dosing 10th December 2019

Write a comment

No comments