Mechanical Components

Displaying 1271 - 1280 of 1482

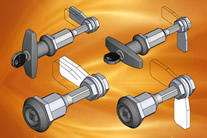

To compress or not to compress? EMKA have the answer locked up!

Compression lock technology has seemed to be rather confined to a limited range of applications until it recently came out of patent protection and now a much wider market is finding it beneficial. EMKA have had their own parallel version of this technology under development for some years and are now able to bring their special expertise in design/manufacture to provision of many compression latch variants.

13th May 2009

Lean manufacturing drastically cuts ring slide lead time

As well as the continual development of its products HepcoMotion is also committed to the continual development of its manufacturing processes. And with this as the motive the Tiverton-based company has recently taken advantage of a programme offered by the South West Manufacturing Advisory Service. The result has been the introduction of lean manufacturing techniques that have given rise to important benefits for ring slide customers.

13th May 2009

VAPOURWASH – A genuinely safe alternative to solvent degreasing

Manufacturers can now have a safe alternative to vapour solvent degreasing, yet still achieve effective and consistent high integrity precision cleaning. The launch of the new Vapourwash machine from degreasing manufacturers Technowash, is the first fully aqueous based alternative vapour degreasing system available on the market, and is a significant development in the continued campaign to reduce solvent usage in the workplace.

8th May 2009

Jena Tec WBSVH Grinding Attachment for Vertical Lathes & Turning Machines

Adaption of a vertical turret lathe or turning centre into having a grinding capability couldn't be easier with the use of a Jena Tec WBSVH grinding head.

7th May 2009

SKF dry lubrication boosts line efficiency safely

The latest VOGEL dry lubrication technology from SKF is enabling line efficiency to be optimised safely and cost effectively across a diverse range of food and beverage applications. A dry film of lubricant is distributed by a central system, minimising lubricant consumption and eliminating the cost and operational implications of using water-based lubricants.

5th May 2009

Boron free coolant meets every EU need

Master Chemical’s TRIM C270 is a high performance synthetic cutting and grinding fluid that is the preferred choice of many manufacturers worldwide. Rolls Royce is a good example where TRIM C270 holds its CSS130 approval. Even though this product still attracts high acclaim it has nevertheless been the subject of continuous development and now a new variant is set to become as popular as its forerunner.

28th April 2009

Elesa oil level indicators in brass and stainless steel

Elesa have introduced Brass bodied versions of their high specification oil level indicators with scratch resistant glass. These are likely to be of interest for external applications where electrical continuity and low spark energy are required, coupled with clarity of readings even under abrasive conditions.

28th April 2009

Achieve energy efficiency with 60 % less consumption

Energy chain systems not only transport energy, data and media to machines and systems. They also influence their energy consumption costs. How much pull-push force, or driving force, is required at a given speed to move an energy chain? How light or stable do energy chains have to be for minimum energy to be consumed? Modern plastic energy chains and Chainflex® cables from igus UK, help in the design and operation of machines that are efficient in terms of energy and cost.

23rd April 2009

Mechanical Components documents

Datasheets

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex