Machining

Displaying 41 - 50 of 460

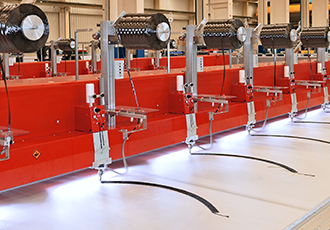

Wireless spindle positioning system speeds accurate machine set up

Elesa have introduced a wireless spindle positioning system, which enables faster and more reliable machine set up by use of a wireless connected profile controller, and displays the initial set up values on each of up to 36 electronic position indicators. The operator can simply choose the appropriate menu then quickly re-set each spindle to its correct start position and the machine is ‘good to go.’ This saves time and takes out much of the possibility of human error.

13th November 2018

Experts attend PPMA to improve food cutting processes

Emerson experts will be in attendance at PPMA 2018 in the NEC arena. They will demonstrate how the application of Branson ultrasonic cutting technology can help customers from within the food manufacturing and processing industries deliver a cleaner and better cut quality. Ultrasonic cutting enables smoother penetration of the item being cut.

24th September 2018

Precision double mitre cutting bandsaw

German sawing machine manufacturer, KASTO, is supplementing its bandsaw programme with the addition of a twin-column machine for cutting stock to length and mitring between -45 and +60° to a high degree of precision. The KASTOmiwin saw is said to be ideal for use by steel stockholders due to its power and rigidity.

7th September 2018

Solid state relays improve speed of injection moulding machines

A new range of Solid State Relay (SSR) products from Sensata Technologies are helping operators of injection moulding equipment to improve the quality, speed and output of their manufacturing operations.

20th August 2018

Adjustable side milling cutter for grooving

A new side milling cutter for stepless adjustment of groove width has been introduced by Paul Horn and is available through the firm's UK subsidiary, Horn Cutting Tools, Ringwood. The milling body features a central sleeve that enables the required groove width to be adjusted easily on a pre-setter.

20th August 2018

Titanium aircraft parts produced 25% faster

The largest producer of Horizontal Machining Centres (HMCs) in the UK, Heller Machine Tools, has supplied a large, heavy duty machine to GKN Aerospace Filton, near Bristol, to rough titanium aircraft components. It was installed on budget and ahead of schedule during the latter part of 2017.

17th August 2018

Versatile alternative to a driven-tool lathe

Tony Bess, Director of Subcontract Machinists Plalite, has invested £3m in capital equipment in three years, including purchasing two Japanese-built Speedio M140X2 30-taper mill-turn centres from Brother, supplied by Whitehouse Machine Tools. The first of the five axis machines was installed in mid-2017 and proved so successful that a second was added six months later.

8th August 2018

How misalignment in rotating machinery can affect you

If the coupling and shaft in your rotating machinery is not aligned correctly, it may reduce the longevity of your machines. What’s more, misalignment may be responsible for up to 50% of all costs relating to rotating machinery failures. Why? Because of excessive vibration and temperature increases that cause the risk of premature bearing, coupling and shaft failure.

30th July 2018

.jpg)