Machining

Displaying 371 - 380 of 460

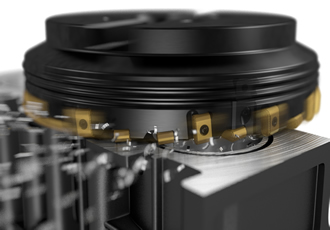

MAPAL develops new cutting material series for boring

Tools with ISO elements (inserts) are first choice when it comes to the boring of cast materials. As the need for high cutting speeds and better cooling technologies rises, the demands on the tools and cutting edges increase, too. Very good friction and wear behaviour and high hot hardness of the coating are therefore elementary. Until now boring operations have been widely performed using PVD-coated cutting edges.

8th December 2015

Time based data capture software package

Renishaw introduced Ballbar Trace at EMO 2015; a new time based data capture software package for the company's QC20-W ballbar which is used to verify the positioning performance of CNC machine tools. The new software is free of charge to existing QC20-W users and opens up many new applications, including static monitoring and data capture for ISO 10791-6, and also reduces test setup time for the system. To accompany Ballbar Trace a new version of XCal-View data analysis software will also be released to provide enhanced data analysis.

1st December 2015

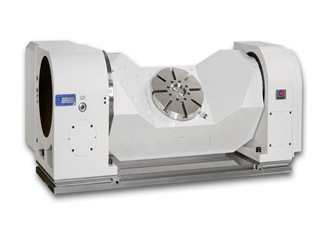

Leader supports multi-axis manufacturing

Leader Chuck Systems has recently added the Exact Machinery range of precision CNC rotary tables and indexing units to its extensive product portfolio. The Taiwanese company has over two decades experience, continuously developed new and innovative products to improve the manufacturing processes and productivity for precision engineering companies in every industrial sector. The ISO 9001 accredited 180-strong company produces over 3,000 units each year at its 4,800 m2 state-of-the-art manufacturing facility.

26th November 2015

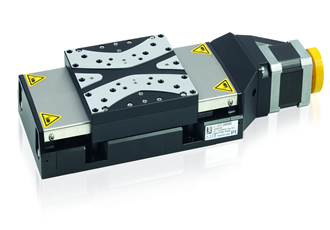

New Precision Linear Stepper Stage from PI, L-511

Physik Instrumente (PI) presents the L-511 linear stage series featuring minimum incremental motion as small as 0.02µm. With travel ranges to 155mm (6 inches), this 2-phase micro stepper motor platform is ideal for precision positioning demanded by science and industry, especially with high duty application cycles. Vacuum compatible versions are available.

10th November 2015

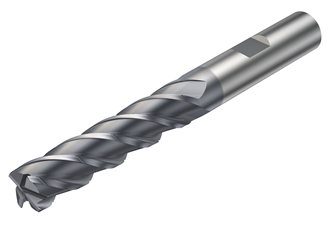

Better Engineering Means Higher Productivity in Titanium and Stainless Steel With New VariMill III ER From WIDIA

With a new seven-flute, eccentric relief (ER) design, the newest addition to the WIDIA VariMill family, the VariMill III ER solid-carbide end mill, is engineered for higher metal removal, longer tool life, and improved surface finishes in demanding workpiece materials such as titaniums and stainless steels.VariMill III ER is true finishing endmill for higher metal removal rates, longer tool life, and improved surface finishes in demanding workpiece materials such as titaniums and stainless steels.

9th November 2015