Machining

Displaying 101 - 110 of 460

It's all about the experience, tradition and passion

To ensure five-star quality at the five-brother company Bühler Bedachungen und Bauspenglerei from Romanshorn in Switzerland, three qualities are essential – experience, tradition and passion. The business that specialises in roofing and architectural sheet metal puts quality at the top of the list for priorities, particularly when it comes to selecting its partners and suppliers.

27th November 2017

Reliable and robust ergonomic tool provides maximum productivity

At this year’s productronica, it is the PAT 4.0 Automatic Cable Tie Installation System that is shining bright for Panduit Europe, a company in wire harness, heavy duty cable management, and control panel solutions for over 60 years, who are showing customers the PAT 4.0 is designed to maximise bundling productivity with gains of up to 25% over other automatic cable tie systems and over six times the speed of manual cable tie methods.

17th November 2017

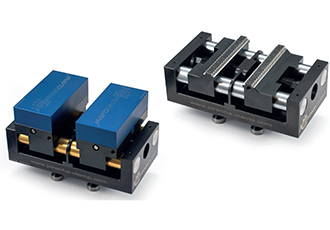

Clamping down the force on verification systems

Two new systems designed for checking how tightly a component has been clamped have been announced by workholiding equipment manufacturer, OK-VISE. The design is mindful that during automated machining in particular parts need to be clamped, and verifying holding force has always been a challenge. The Finnish-made products are available in the UK through 1st Machine Tool Accessories, Salisbury.

13th November 2017

New level of sophistication brought to paint spraying machines

Paint spraying machine users can now benefit from easier set-up, reduced down-time and an assurance of future proofing in the wider production environment, thanks to Progea’s Movicon control and visualisation software. Based in Imola, Northern Italy, CELFA is a manufacturer of computerised paint spraying machines. The company applies advanced technology and automation solutions that combine the highest levels of spraying quality and precision with an energy saving and eco-friendly design.

13th November 2017

High specification in universl lathe

A powerful universal turning machine has been introduced by DMG MORI as the CTX 2500|700, for machining components up to 366mm in diameter from billet or 76mm from bar and to a maximum length of 705mm. Class-leading performance is claimed by the manufacturer, Gildemeister Drehmaschinen, whose managing director Harry Junger commented: “For the first time we can turn grooves up to 12mm wide in CK45 steel and drill holes to 80mm diameter.”

10th November 2017

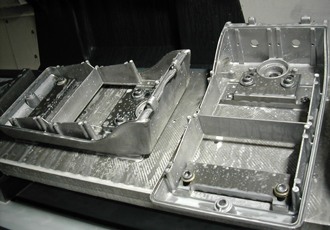

System speeds up toolmaking and production machining

From ten die casting machines, W. Hallam Castings’ foundry produces around 20,000 aluminium castings per week. Established in 1968 it now produces parts for a range of applications including industrial and domestic air conditioning systems, office furniture, DIY equipment, lighting and computer products. As part of its service, the company carries out powder coating and assembly operations to deliver a finished product to its customers.

1st November 2017

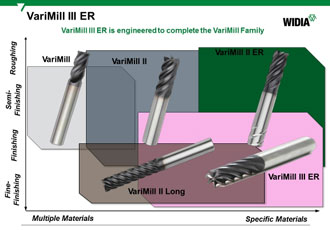

High speed machining for aerospace applications

The metal cutting industry continues to develop in order to meet the advanced requirements of the various industrial applications. High speed machining meets the demands of industries which are required to produce high quality tools. These industries include the car manufacturing industry, space and aviation industries, and medical industry.

30th October 2017

F1 subcontractor expands with 5-axis machining

At a High Wycombe engineering company many years ago, Ray Harris started out on a five year mould and tool making apprenticeship, at just 16 years old. After two years he left as much of this type of work was being offshored and he could see little future in it. Harris moved to a nearby subcontractor that specialised in supplying components for Formula 1 and has worked in the industry ever since, both in the supply chain and in-house for two leading F1 teams.

16th October 2017