When to choose an ironless DC motor

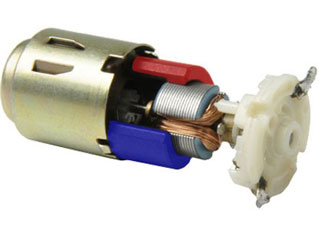

Many engineers consider a low voltage DC permanent magnet motor as something they would find at home in tools and appliances. This is the more conventional iron core DC motor where the windings are wrapped around an iron core with the magnet on the outer casing. Often this as the first type of motor we are introduced to in our science class in school.

By Paul Williams, Senior Sales Engineer at Maxon Motor

The iron core DC motor is used in millions of drive systems; providing a low cost solution for many commercial applications, powering everything from toys to car mirrors. They are cheap to manufacture and are produced in high volumes.

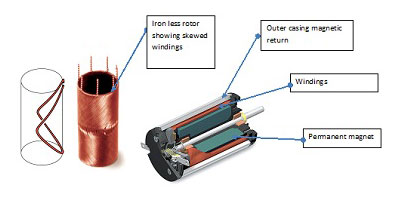

Perhaps a lesser known technology used on small DC permanent magnet motors is that of the ironless rotor design. These motors can be found in many devices where high speed servo performances are required, such as robotics; X-ray drives; prosthetics; lab analysis equipment; thermal imaging; radar drives and high end record decks. Applications using ironless DC motors benefit from a highly dynamic drive, linear speed and torque control with in a high power to size ratio (compact size).

The design is based on a coreless or iron less winding (sometimes referred to as a basket weave or bell type design). The permanent magnet sits underneath the winding, with the outer case of the motor being the magnetic return, this make for a very compact design.

The commutators and brushes of smaller ironless motors are made of precious metals such as silver, gold, platinum or palladium. They have low friction and generate little magnetic interference. The motors work with very low starting voltages and for larger motors they tend to have copper-graphite commutation systems that can handle the higher current.

The advantage of this motor is that there is no iron core so there is no magnetic field to break down. They also have very low inertia.

These factors bring some distinct advantages over a conventional iron core motor.

- No cogging torque and smooth rotation even at low speeds

- Low vibration and low noise operation

- Linear speed/torque characteristics so the motor speed and torque is easily controlled

- Efficiency. The motors are highly efficient at 90%. The motor does not have to break down the magnetic fields. The winding can almost fill the air gap between the magnet and its magnetic return

- As the motors don’t have an iron core, the coil and the magnetic field of the stator is not affected by saturation effects in the magnetic field. This means stronger, more powerful magnets can be used. Many of the ironless rotor motors are using rare earth magnets to maximise performance and size

- The motor winding has a very low inertia as there is no iron core to accelerate. The motor can accelerate and decelerate to full speed in milliseconds, offering very high speed performance

- Due to the absence of iron in the rotor, ironless motors have low winding inductance and thus lower levels of sparking between the brush and the commutator than conventional motors. Arcing normally produces electro-erosion and shortens the motor’s service life, so the motors can last many times longer than a conventional wound motor

Of course the ironless rotor does have some disadvantages.

- More expensive to manufacture

- Cannot tolerate thermal overloads as well as the iron core motors as there is no metal core to act as a heat sink for the rotor windings. They can heat rapidly due to overload and stalling.

To summarise, both iron cored and coreless DC motors have their own benefits and drawbacks, however coreless DC motors are superior in terms of performance as they can operate at very low speeds, due to no cogging torque, yet offer a low inertia which allows high acceleration rates. Consider ironless DC motors for more demanding applications, the ironless motor has higher dynamic performance, higher power to weight ratio’s and longer life than the more familiar conventional DC motor. The efficiency and service life of ironless DC motors is a key selling point, however each application varies and the motor chosen must be suitable for the requirements.

Similar articles

More from Maxon Motor UK Ltd

- The role of motors in laboratory productivity 14th May 2021

- maxon develops ultra-efficient UAV drive with startup Flybotix 13th October 2020

- Smart farming, precision agriculture and Agriculture 4.0 6th July 2020

- What part do DC motors play in the medical industry? 12th March 2018

Write a comment

No comments