Thermal Simulation Tool Reduces IC Cost by Comparing Flip-Chip/Wire Bond Thermal Performance

8th May 2008

Source:

Flomerics

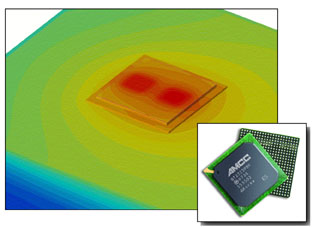

Flomerics announced today that the Package Engineering Group from Applied Micro Circuits Corporation is using Flotherm thermal simulation software to significantly reduce the cost of packaging and the project resource cost for a new family of ICs. AMCC achieved these outstanding results by comparing flip-chip and wire bond thermal performance early in the design process.

“Thermal simulation helps us improve the targeted performance to cost ratio of our leading dual port 10Gbps Ethernet PHY family, the QT2225 and QT2235, by enabling us to optimize the tradeoff between thermal performance and packaging cost at an early stage of the design process,” said AMCC® Packaging Engineer Mark Patterson. “The ability to generate thermal models of ICs in less than an hour removed the barriers of simulation complexity and time/resource constraints at the early stage of our design process.We use Flotherm for thermal simulation because it makes it easy and convenient to model different package styles and types.”

A key advantage Flomerics brings to its customers is greatly reducing the time required to model the package design alternatives using the Flopack website. By simply defining the key parameters of the chip including the package size, die size, number of balls, number of metal layers in the package and power dissipations, the Flopack web site then created detailed thermal models of each type of package in a fraction of the time that would have been required to model the geometry from scratch or using alternate solutions.

On nearly every new product, AMCC also uses thermal simulation to create a design guide that provides customers with detailed thermal performance information under specified conditions. A typical design guide is a detailed engineering document that makes it clear to customers what is required to keep the chip cool under a wide range of conditions. AMCC also creates compact models for most of its products. These compact models provide a quick and simple prediction of the component’s response to changes in airflow, temperature, and pressure. AMCC provides these models to customers who incorporate them into Flotherm models that they then use to predict the thermal performance of their complete systems.

A key advantage Flomerics brings to its customers is greatly reducing the time required to model the package design alternatives using the Flopack website. By simply defining the key parameters of the chip including the package size, die size, number of balls, number of metal layers in the package and power dissipations, the Flopack web site then created detailed thermal models of each type of package in a fraction of the time that would have been required to model the geometry from scratch or using alternate solutions.

On nearly every new product, AMCC also uses thermal simulation to create a design guide that provides customers with detailed thermal performance information under specified conditions. A typical design guide is a detailed engineering document that makes it clear to customers what is required to keep the chip cool under a wide range of conditions. AMCC also creates compact models for most of its products. These compact models provide a quick and simple prediction of the component’s response to changes in airflow, temperature, and pressure. AMCC provides these models to customers who incorporate them into Flotherm models that they then use to predict the thermal performance of their complete systems.

Similar articles

More from Flomerics

- Laser Design Offers SLP-500 High-Speed Laser Probe 14th May 2009

- Simulation Helps Develop Spray Gun with 50% Larger Pattern in Significantly Less Time 30th April 2009

- Giles Gaskell Joins Laser Design & GKS Inspection Services Team 17th March 2009

- Embedded CFD Helps Reduce Number of Thermal Prototypes from Up to 12 to 1 4th March 2009

technology at Jacobs Vehicle Systems.JPG)

Write a comment

No comments