Thermal Simulation Helps Design New Telecom Platform That Delivers 40Gbps Bandwidth

5th August 2008

Source:

Flomerics

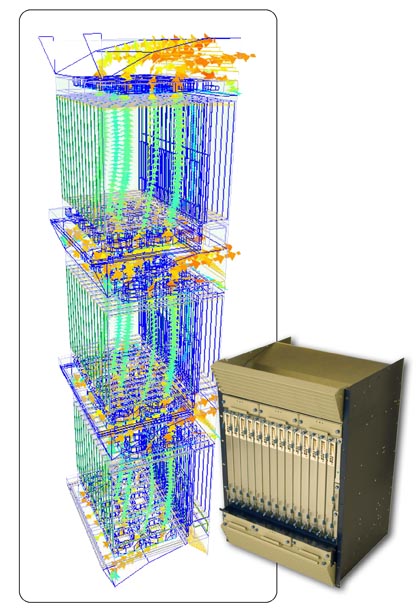

Simclar Group used Flomerics’ Flotherm thermal simulation software to develop a new platform that goes well beyond the Advanced Telecom Computing Architecture (ATCA) 3.0 specification. “Simulation gave me the freedom to consider a wide range of alternative designs by letting me evaluate their performance quickly and at very little cost,” said Dave Watson, Thermal Design Team Leader for Simclar Group. “We succeeded in developing a platform that goes well beyond the ATCA 3.0 specification by delivering 40 Gbps backplane bandwidth and 50 CFM airflow per slot with near-perfect airflow distribution.”

“Thermal simulation was a critical process in our product development,” Watson said. “Thermal simulation is like having X-ray vision. It lets you see inside the box to look at airflow, pressures and temperatures at any point. A single thermal simulation gives you a detailed understanding of what is going on inside the box and helps you quickly identify the root causes of the problem.”

“In the 15-plus years that I have been involved with thermal simulation I have developed a strong preference for Flomerics’ Flotherm software,” Watson said.

“Its user interface is very intuitive, making it possible to rapidly create and manipulate simulations. Flotherm’s visualization editor provides very powerful tools for displaying and animating results. This makes it much easier to understand problems and to explain to others why the design changes that you are recommending are necessary. In addition, many customers use Flotherm, allowing potential sharing and integration of models.”

Watson simulated a “push” airflow system, with the fans located in front of the cards, a “pull” system, with the fans located behind the cards, and a “push-pull” system, with the fan split on both sides of the cards. He also looked at different ways of allocating the available space to plenums at the inlets and outlets. He changed the design to reduce pressure drop as much as possible. The reduction in pressure drop inside the chassis changed the type of fan that would provide the best performance. Watson evaluated multiple fans and selected one that operated very efficiently at the static pressure generated by the optimized chassis design.

“After we identified the ideal fan, I ran a new simulation that showed that we now were delivering more than 50 CFM to each slot and also meeting the 20% air distribution requirement,” Watson added. “The simulations also allowed us to evaluate a number of build variants. We made the chassis design modular so that fan configuration could be switched between push and push-pull and the size of the plenums could be adjusted. The result is that the TurboFabric not only meets the thermal requirements of the foreseeable future but can be upgraded to provide a future-proof solution for telecommunications equipment manufacturers.”

For more information, visit Flomerics' Web site at http://www.flomerics.com

“In the 15-plus years that I have been involved with thermal simulation I have developed a strong preference for Flomerics’ Flotherm software,” Watson said.

“Its user interface is very intuitive, making it possible to rapidly create and manipulate simulations. Flotherm’s visualization editor provides very powerful tools for displaying and animating results. This makes it much easier to understand problems and to explain to others why the design changes that you are recommending are necessary. In addition, many customers use Flotherm, allowing potential sharing and integration of models.”

Watson simulated a “push” airflow system, with the fans located in front of the cards, a “pull” system, with the fans located behind the cards, and a “push-pull” system, with the fan split on both sides of the cards. He also looked at different ways of allocating the available space to plenums at the inlets and outlets. He changed the design to reduce pressure drop as much as possible. The reduction in pressure drop inside the chassis changed the type of fan that would provide the best performance. Watson evaluated multiple fans and selected one that operated very efficiently at the static pressure generated by the optimized chassis design.

“After we identified the ideal fan, I ran a new simulation that showed that we now were delivering more than 50 CFM to each slot and also meeting the 20% air distribution requirement,” Watson added. “The simulations also allowed us to evaluate a number of build variants. We made the chassis design modular so that fan configuration could be switched between push and push-pull and the size of the plenums could be adjusted. The result is that the TurboFabric not only meets the thermal requirements of the foreseeable future but can be upgraded to provide a future-proof solution for telecommunications equipment manufacturers.”

For more information, visit Flomerics' Web site at http://www.flomerics.com

Similar articles

More from Flomerics

- Laser Design Offers SLP-500 High-Speed Laser Probe 14th May 2009

- Simulation Helps Develop Spray Gun with 50% Larger Pattern in Significantly Less Time 30th April 2009

- Giles Gaskell Joins Laser Design & GKS Inspection Services Team 17th March 2009

- Embedded CFD Helps Reduce Number of Thermal Prototypes from Up to 12 to 1 4th March 2009

technology at Jacobs Vehicle Systems.JPG)

Write a comment

No comments