Active Chilled Beam Cooling Reduces Energy Usage 20% in Northwestern Lab

9th May 2008

Source:

Flomerics

An active chilled beam cooling system played a key role in delivering an expected 20% reduction in cooling and ventilation energy consumption at the new Genomic Science Building at the University of North Carolina in Chapel Hill, North Carolina. The system was developed by Affiliated Engineers, Inc. in collaboration with the project architect, Skidmore, Owings, and Merrill LLP. Engineers at Affiliated Engineers, Inc. used Flomerics’ Flovent computational fluid dynamics software to optimize the cooling system and maximize the energy savings.

The Genomic Science Building is a $125 million research laboratory that will provide approximately 210,000 square feet of modern classrooms, laboratories and offices including nine wet labs, four bioinformatics labs, a 250 seat lecture hall, a 450 seat lecture hall, an 80 seat classroom, and four 30 seat seminar rooms. The projected construction start date is February 2009 and the projected construction completion date is February 2011.

“AEI was looking at ways to improve energy efficiency for the building,” Talbert said, “and chilled beams can be very promising in laboratories with equipment driven loads.” To evaluate the viability of this approach, AEI needed first to determine the type and size of chilled beam system that would be needed to cool the laboratory and then estimate the amount of energy that this system would consume.

AEI used Flovent CFD to simulate the operation of the HVAC system. “We selected Flovent software because it has the capability to model complex heating and cooling systems and provides the temperature and airflow feedback necessary to determine the effectiveness of the system design,” Talbert said. “Flomerics also provides support representatives who are not only knowledgeable about the software but are also experienced in addressing the challenges of designing HVAC systems.”

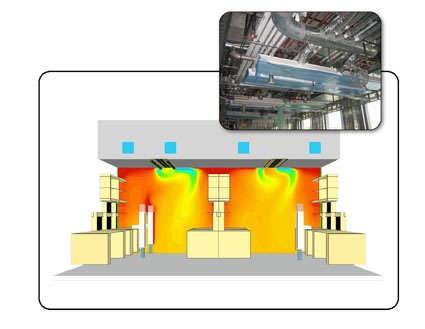

In lieu of modeling a whole laboratory, a representative laboratory bench module was selected in order to reduce input and simulation time. An active beam cooling system was modeled which has two airflows, the airflow that is forced through the beam nozzles and the airflow induced by the lower temperature and negative pressure in the beam. His goal was to design an active chilled beam system that would meet the temperature requirements for the space while reducing overall energy consumption. A variety of active beam scenarios were analyzed and a design that met this objective was identified. .

AEI then used the resulting chilled beam capacities and ventilation requirements to inform the input to an annual energy consumption simulation for the laboratory space. In addition to the chilled beam and ventilation system descriptions, the energy simulation includes annual operational schedules, internal loads, and weather data. The energy analysis predicted that the energy consumption of the laboratory conditioning systems will be about 20% lower than a baseline comparison for conventional designs based on American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE) Standard 90.1-2004. These improvements played a key role in the energy-efficient design of the new building, which is being designed to obtain a Silver certification rating under the Leadership in Energy & Environmental Design® (LEED) program from the United States Green Building Council when it is completed.

For more information about Flovent, visit http://www.flovent.com

“AEI was looking at ways to improve energy efficiency for the building,” Talbert said, “and chilled beams can be very promising in laboratories with equipment driven loads.” To evaluate the viability of this approach, AEI needed first to determine the type and size of chilled beam system that would be needed to cool the laboratory and then estimate the amount of energy that this system would consume.

AEI used Flovent CFD to simulate the operation of the HVAC system. “We selected Flovent software because it has the capability to model complex heating and cooling systems and provides the temperature and airflow feedback necessary to determine the effectiveness of the system design,” Talbert said. “Flomerics also provides support representatives who are not only knowledgeable about the software but are also experienced in addressing the challenges of designing HVAC systems.”

In lieu of modeling a whole laboratory, a representative laboratory bench module was selected in order to reduce input and simulation time. An active beam cooling system was modeled which has two airflows, the airflow that is forced through the beam nozzles and the airflow induced by the lower temperature and negative pressure in the beam. His goal was to design an active chilled beam system that would meet the temperature requirements for the space while reducing overall energy consumption. A variety of active beam scenarios were analyzed and a design that met this objective was identified. .

AEI then used the resulting chilled beam capacities and ventilation requirements to inform the input to an annual energy consumption simulation for the laboratory space. In addition to the chilled beam and ventilation system descriptions, the energy simulation includes annual operational schedules, internal loads, and weather data. The energy analysis predicted that the energy consumption of the laboratory conditioning systems will be about 20% lower than a baseline comparison for conventional designs based on American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE) Standard 90.1-2004. These improvements played a key role in the energy-efficient design of the new building, which is being designed to obtain a Silver certification rating under the Leadership in Energy & Environmental Design® (LEED) program from the United States Green Building Council when it is completed.

For more information about Flovent, visit http://www.flovent.com

Similar articles

More from Flomerics

- Laser Design Offers SLP-500 High-Speed Laser Probe 14th May 2009

- Simulation Helps Develop Spray Gun with 50% Larger Pattern in Significantly Less Time 30th April 2009

- Giles Gaskell Joins Laser Design & GKS Inspection Services Team 17th March 2009

- Embedded CFD Helps Reduce Number of Thermal Prototypes from Up to 12 to 1 4th March 2009

technology at Jacobs Vehicle Systems.JPG)

Write a comment

No comments