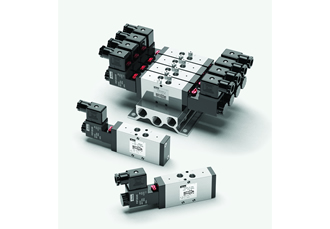

Expanded Viking Lite Range Offers a Robust and Versatile Solution

Parker Hannifin has developed an Air Piloted pneumatic solution for its Viking Lite Range. Developed in response to customer’s needs, this new addition allows the high performing range of value engineered directional control valves to be specified in applications where air pilot is required.

Delivering high performance at a reasonable cost, the Viking Lite series offers a choice of three port sizes (G1/8, G1/4 and G3/8) and has a compact design, direct body porting and integral mounting holes for a flexible solution that can be specified in a wide range of industrial applications. Manufactured from anodized aluminium, Viking Lite offers a valve with excellent corrosion resistance and, with a smooth body to eliminate dirt-collecting pockets, suitability for a wide variety of environments. The addition of the Air Piloted solution expands this flexibility to deliver high performance in all pneumatic operations.

As a highly cost-effective solution, utilising Viking Lite helps to reduce maintenance costs and service time. Through its Wear Compensation System, Viking Lite valves deliver robust performance for a longer service life with short changeover times and low changeover pressure for reduced service time. Fitted with Parker’s dynamic bi-directional spool seals, the range can operate comfortably at pressure up to 10 bar and in ambient temperatures from -10ºC to 50ºC and deliver a staggering 10 million operating cycles.

In addition to single valve installation, Viking Lite gives customers the flexibility to install the valves in two ways; a manifold bar installation with common ducts for ports 1, 3 and 5, giving a simple, time saving and easily serviced solution available in several different sizes, with space for between 2 and 14 valves, or a pressure bar installation for common primary air supply providing a simple, robust, time saving and easily serviced installation. When pressure bars are used, restrictor-silencers can be installed in the exhaust ports of each valve, for individual adjustment of cylinder / air motor speed. Pressure bars are available in a number of different sizes, with space ranging from 2 to 10 valves.

Similar articles

More from Parker Hannifin

- Flange system gains new certification for marine applications 4th June 2021

- New generation of oil condition monitoring technology 2nd June 2021

- Parker introduces new low GWP refrigeration dryer series 24th November 2020

- Steering into the future for mobile machinery 17th November 2020

Write a comment

No comments