Digital PpQ control for Hydrokraft pumps improves performance

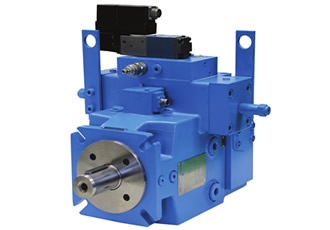

Launching a digital PpQ control unit, Eaton, designed for its high pressure pump in W design and variable displacement pumps – Hydrokraft PVW – which enables users in the marine industry to achieve better control, faster response time, higher reliability, and cost savings through a reduced overall component count.

The PpQ unit electronically controls displacement (flow), pressure and power on the pump and additional operational costs and environmental impact may be reduced through energy recovery as the control unit allows the pump to be used 100% overcentre, functioning as a motor for counter moving applications like, for example, lifting and lowering.

The Hydrokraft PVW variable axial piston pumps with a swash plate design help provide reliable operation and a long operation life. The key features of these pumps make them relevant for marine and other similarly demanding offshore and onshore applications. They offer fast response times together with rated pressure of 350bar (420 maximum), rated speed up to 1,800revs/min and displacement sizes ranging from 130-500cm3 per revolution. Reliability is enhanced with oversize shafts and bearings, with pressure balancing of rotating and pressure-loaded parts.

The PpQ control unit comprises an electronic controller and a proportional valve, which controls the pump for pressure, power and displacement, without mechanical control. It also adds intelligent mooring control and master/slave functions.

Flow control measures the actual swash-plate position from sensor data, comparing the swash-plate angle with the set value and driving the servo or proportional valve accordingly. Swash plate angle as well as pump displacement and outlet flow are regulated to match set values.

Pressure cut-off control measures pressure sensors both in and output pressure lines, reducing output levels if actual pressure exceeds the command signal. This adjusts the pump more closely to the overall application.

Power cut-off control calculates actual power by measuring pressures and swash plate angle, which are directly proportional to flow. Should power exceed command signal levels, the controller generates a maximum internal flow command signal in line with the maximum input power.

A master to slave function allows several pumps to be used to facilitate large-scale applications with high flow demand. In this mode the master pump can be synchronised over its full operational and flow span, while the slave pumps follow the master pump settings. A through drive allows multiple pumps from a single shaft.

The electronic PpQ control is implemented with Eaton’s ER9.X-10 digital amplifier and controller card assembly, which meets industrial EMC, EMV, shock and vibration standards. It features four seven-segment displays and six buttons to adjust card parameters easily. Configuration is also possible via an RS232 serial interface and the ER9.X-Tool software provided.

Giuseppe Scozzarella, Product Manager, EMEA Industrial Hydraulics at Eaton said: “Eaton works closely with its customers in the marine industry worldwide, providing expert advice on how they can operate efficiently.”

Scozzarella added: “For example, in one innovative large-scale marine application, Eaton adapted its Hydrokraft pumps with electronic controls for use with intelligent MAN diesel engines, saving fuel and reducing emissions.”

He continued: “As well as marine implementations, the Hydrokraft pumps, with their modular design, suit many demanding applications like offshore installations, test rigs and simulators, materials handling and recycling, primary metal power units and oil and gas production. And by applying the pumps, our customers will gain a competitive advantage and reduce costs; they are unique to Eaton as engineering solutions, allowing us to position Eaton as a leader in the industry technologically.”

Similar articles

More from Eaton Corporation

- IP-based automation system for underground applications 20th November 2020

- Engineering expertise keeps the blades turning 28th September 2020

- Blowout preventer hoses exceed the latest fire test requirements 9th October 2019

- Enhancing configuration software and increases flexibility 15th May 2018

Write a comment

No comments